2020.10.16

INDUSTRY NEWS - 2020.10.16

1、進博會成果落地激發"中國制造"創新動力

在浙江新澳紡織的智能車間里,一台台進口紡紗設備代替了傳統工人,車間中難尋一人,根根紗線卻織造不斷頭。這些來自意大利、德國的先進設備,都是在進博會上簽下的。對標國際先進水平,產生先進理念、技術、工藝和管理模式的溢出效應,新澳紡織的例子只是一個縮影。盤點兩年來進博會的成果,開放的平台正在推動中外制造業不斷擴大交流,帶動更新的技術應用在中國落地生根。

引入進口設備

"當前紡織業間的競爭,最根本的落腳點就在於智能制造裝備。"首屆進博會上,浙江新澳紡織股份有限公司設備部經理平根富把最多的時間花在了裝備展區。

通過參加進博會,這兩年,新澳紡織積極引進國外先進紡紗設備,減少各工序的人力資源消耗。2019年,該公司的進口額達到1.71億元,其中進口設備占到1.69億元。"這些設備主要用於紡紗工藝,相較於之前的設備,不僅提高了產品的穩定性,也提升了裝備的自動化程度。"平根富說。

記者了解到,新澳紡織向意大利聖安德烈、德國賜來福等國際先進紡機企業下單,先後投產"30000錠緊密紡高檔生態紡紗項目"和"60000錠緊密紡高檔生態紡紗項目"。新設備同原設備相比,在產能相同的情況下,前紡工序平均節省1人/台,細紗工序平均節省1.5人/台,"機器換人"效果顯著。

而作為我國最早從事集成電路和半導體元器件研发、生產的半導體封裝領軍企業之一,甘肅天水華天電子集團則在前兩屆進博會上,先後與先進太平洋(香港)有限公司(ASM)和日本DISCO14公司簽署了設備材料購買意向書,簽約商品為半導體封測設備材料等。

通過引進全球先進的集成電路封測設備,華天持續不斷地進行產業升級和技術改造,如今已掌握全球先進的TSV、3D、FC、WLCSP等封裝技術,有效促進企業高質量发展,助力打造中國集成電路封測行業的第一品牌。

"中國制造"升級

中國市場對全球企業有著超強磁場效應,除了輸出產品和技術,跨國公司也和中國夥伴攜手合作,在華投產投資,共同擘畫技術藍圖,加速"中國制造"轉型升級。

作為全球第一大商用直升機制造商,意大利萊奧納多公司在前兩屆進博會上展出的直升機彈眼落睛,成為參觀者爭相合影的網紅展品。而在第三屆進博會上,其在嘉興平湖制造的第一架直升機將在展會現場交付。從"意大利制造"到"中國制造",兩年多的時間里,到底发生了什麽?

原來,意大利萊奧納多公司借助進博會這個大平台,不僅簽下了采購大單,還找到了中國夥伴,把生產基地設在了長三角。在首屆進博會上,上海正陽集團與意大利萊奧納多公司簽署戰略協議,總投資128億元,在張江長三角科技城平湖園建設總裝生產線及交付中心,主要承擔阿古特斯公司AW139和AW 169直升機的組裝制造、試驗試飛及配套任務。

按照"第一年簽約、第二年開工、第三年交付"的計劃進度,目前該項目已進入實質性建設階段,40畝研发中心大樓已開工建設,133畝交付中心也相繼開工,計劃2020年第一架直升機下線,並在今年進博會現場交付。

"在集中展示國外新技術、新產品、新服務的同時,進博會這個開放的平台正在激发'中國制造'的創新動力,倒逼企業加速轉型升級。"中國宏觀經濟研究院產業經濟與技術經濟研究所副主任盛朝迅說,在對標世界先進水平的過程中,中國制造企業正加大新產品、新技術的研发力度和智能化、綠色化、高端化的改造步伐,彌補工業基礎能力和"卡脖子"短板,不斷提高產品質量和創新能力,在新一輪科技革命和產業變革中實現跨越式发展。

資料來源:mp.weixin.qq.com (2020年10月10日)

2、習:全面擴開放 賦深圳更多自主權 世界百年大變局 中國決不被逆風所阻

深圳經濟特區建立40周年慶祝大會昨(14日)舉行,中共總書記習近平在會上發表講話表示,世界正經歷百年未有之大變局,經濟全球化遭遇逆流,但中國決不被逆風和回頭浪所阻,要堅定不移全面擴大開放。

他強調,推動以國內大循環為主體、國內國際雙循環相互促進的新發展格局;並支持深圳實施綜合改革試點,以清單批量授權方式,賦予深圳在重要領域和關鍵環節改革上更多自主權。

更高起點拓創新 贏主動權

習近平稱,當今世界正經歷百年未有之大變局,新冠肺炎疫情全球大流行使這個大變局加速演進,經濟全球化遭遇逆流,保護主義、單邊主義上升,世界經濟低迷,國際貿易和投資大幅萎縮,國際經濟、科技、文化、安全、政治等格局都在發生深刻調整,世界進入動盪變革期。

而中國經濟正處於轉變發展方式、優化經濟結構、轉換增長動力的攻關區,實現高質量發展還有很多短板弱項,經濟特區發展也面臨一些困難和挑戰,因此要堅持改革不停頓、開放不止步,在更高起點上推動改革開放,推動經濟特區工作開創新局面。

在中美科技戰背景下,習提出,必須堅持創新是第一動力,在全球科技革命和產業變革中贏得主動權。

發展數字經濟 加大基礎研究

他提到,要圍繞產業鏈部署創新鏈、圍繞創新鏈布局產業鏈,前瞻布局戰略性新興產業,培育發展未來產業,發展數字經濟。要加大基礎研究和應用基礎研究投入力度,發揮深圳產學研深度融合優勢,主動融入全球創新網絡。要實施更加開放的人才政策,引進培養一批具有國際水平的戰略科技人才、科技領軍人才、青年科技人才和高水平創新團隊。

習又指出,新時代中央賦予深圳的歷史使命,稱深圳是大灣區建設的重要引擎。中共中央經過深入研究,決定以經濟特區建立40周年為契機,支持深圳實施綜合改革試點,以清單批量授權方式,賦予深圳在重要領域和關鍵環節改革上更多自主權,一攬子推出27條改革舉措和40條首批授權事項。深圳特區要扛起責任,牢牢把握正確方向,解放思想、守正創新,努力在重要領域推出一批重大改革措施,形成一批可複製、可推廣的重大制度創新成果。

此外,習近平昨日還到蓮花山公園,向鄧小平銅像敬獻花籃。網傳影片顯示,大批民眾在公園車道兩旁夾道歡迎,習近平打開車窗,向車外民眾揮手。

習籲港青北上 抓住3大歷史機遇

中共總書記習近平在深圳發表講話時談及港澳未來發展,指要充分運用粵港澳合作平台,多吸引港澳青少年到內地學習、就業,並透過人才培育,推動以創新為動力的高品質及可持續發展。

吸年輕人到大灣區學習就業

習近平昨講話後段,特別談到港澳發展,表示深圳是大灣區建設的重要引擎,要繼續鼓勵引導港澳台同胞和海外僑胞充分發揮投資興業、雙向開放的重要作用,在經濟特區發展中作出新貢獻;同時,吸引更多港澳青少年來內地學習、就業、生活,促進粵港澳青少年廣泛交往、全面交流、深度交融,增強對祖國的向心力。

他又提出多個發展方向,希望香港及澳門抓住大灣區建設重大歷史機遇,包括:1)推動三地經濟運行的規則銜接、機制對接,加快大灣區城際鐵路建設,促進人員、貨物等流動;2)深化前海深港現代服務業合作區改革開放,規劃建設好位於河套地區的深港科技創新合作區,加快橫琴粵澳深度合作區建設;3)以粵港澳大灣區綜合性國家科學中心先行啟動區建設,加強與港澳創新資源協同配合等。

全球化遇逆流 習南下部署十四五

「當今世界正經歷百年未有之大變局!」中共總書記習近平昨天在深圳經濟特區建立40周年慶祝大會上講話,對世界局勢作出研判。他強調面對變局,中國要全面擴大開放深化改革,推動國內大循環為主體、國內國際雙循環相互促進的新發展格局。

習近平是次南下廣東一系列考察活動和公開講話,主要圍繞近年來中國內外形勢變化,宣示中央最新的因應之策。同時,也為本月底召開的中共十九屆五中全會即將審議的十四五規劃(2021至2025年五年規劃)綱要,及2035年遠景目標進行「熱身鋪墊」。

為五中全會「熱身鋪墊」

他強調,面對經濟全球化遭遇逆流,世界進入動盪變革期,中國決不被逆風和回頭浪所阻,要堅定不移全面擴大開放,推動構建開放型世界經濟。他認為,中國國內經濟長期向好,市場空間廣闊,正在形成以國內大循環為主體、國內國際雙循環相互促進的新發展格局。

習近平上述的政策宣示,歸納起來,可以總結為,無論國際風雲如何變幻,中國未來始終走開放改革之路不動搖。同時,也面對國際環境不確定性的現實,立足「國內大循環為主體」。

在抵達深圳前,新華社周二(13日)引述習近平在潮汕考察時說:「現在我們正經歷百年未有之大變局,要走更高水平的自力更生之路。」

彭博社認為,習近平提到的所謂「百年未有之大變局」,明顯指中美關係惡化,以及全球新冠疫情對中國經濟造成的衝擊。而「自力更生」,則與習近平最近提出的以「內循環」為主、國內國外「雙循環」的政策相呼應。

中國人民大學財金學院副院長趙錫軍早前表示,未來5年,中國將以經濟「雙循環」因應中美衝突和全球不確定,這意味國內經濟優先。

資料來源:香港經濟日報 (2020年10月15日)

3、深圳改革宏圖 香港如何拍住上?

中央的深圳未來5年改革方案,提及2025年做出可複製的重大制度成果,強化深圳在粵港澳大灣區發展的核心「引擎」。到底,香港將來如何憑藉自身優勢,與深圳一起「拍住上」?

深圳特區成立40周年慶祝大會今日舉行。國家主席習近平南巡之際,中央日前公布《深圳建設中國特色社會主義先行示範區綜合改革試點實施方案(2020-2025年)》。特首林鄭月娥接受內地媒體訪問,坦言「希望中央繼續讓深圳有先行先試、突破性、創新政策,令深港合作可在全新平台進行」。

大灣區科創中心 深港需合作

不過,相信不少港人關心,將來香港於大灣區的地位會否被深圳取代?中方消息人士強調,據《粵港澳大灣區規劃綱要》,香港、澳門、廣州及深圳定位為4大中心城市,當中沒有任何領導關係,即是無提及「龍頭」,關鍵在於「互補和分工」。《綱要》目標明確,旨在建設大灣區成為「國際科技創新中心」,當中尤需要香港和深圳合作。

至於深圳改革方案,只是進一步明確深港合作發展方向和路徑,例如:一、對於兩地共同打造國際科創中心及金融中心,提供相當大的政策支持;二、建設大灣區數據平台,亦有利香港與內地的科研機構合作。

有資深建制派亦指,作為大灣區組成部分,區內城市合作只是相得益彰,所以面對深圳第二次改革開放,大家應思考如何坐順車,「與其眼紅他人,倒不如想辦法分一杯羹」。

維持金融中心 培育科研人才

據了解,今年5月中央曾公布「金融30條」,被視為中央支持香港維持國際金融中心地位,亦有望年底進一步公布落實細節,當中包括跨境理財通機制,支持大灣區居民,通過港澳銀行購買港澳銀行銷售的理財產品,以及開展本外幣合一的跨境資金池業務試點等。

此外,月底召開的中共十九屆五中全會,將提出十四五規劃的方針。

港區人大代表、前海管理局香港事務首席聯絡官洪為民及多名學者早前建議,隨着美國限制中美科研交流,當局可考慮推動香港發展為國際人才中心,向國內輸送科研人才。不要忘記,研發環保無人船的雲洲智能科技張雲飛,還是開發全球消費無人機的大疆創新科技汪滔,都是科大培育的學生,如今已在各自領域大放異彩。

資料來源:香港經濟日報 (2020年10月14日)

4、迅銷少賺44% 新財年擴門店至3725間

【本報訊】UNIQLO、GU母公司迅銷(06288)公布,截至8月底止全年純利跌44.4%至903.6億元(日圓,下同),經營溢利跌42%至1,493.5億元。迅銷擬派末期息240元,全年派息合共480元,派息比率達54.2%。

期內,總收入跌12.3%至2萬億元。迅銷稱,下半年度受疫情影響,世界各地的門店在數個月期間紛紛臨時停業,顧客亦減少外出導致客流量下降,而且該財年門店等減值虧損錄得230億元。毛利率下降0.3個百分點。

日本UNIQLO收入跌7.6%至8,068億元,經營溢利反增長2.2%至1,046億元,全年度同店銷售淨額(含網路商店)跌6.8%;海外UNIQLO收入跌17.7%至8,439億元,經營溢利挫63.8%至502億元。

大中華地區 佔收入逾2成

按地區而言,大中華地區為日本以外最大市場,佔總收入逾2成,全年度收益下跌9.3%至4,559億元,經營溢利跌26.3%至656億元。

至於姊妹品牌GU,全年度收益按年增3.1%至2,460億元,惟經營溢利跌22.5%至218億元,同店銷售淨額跌5.2%。但第四季度收益恢復,單季同店銷售淨額按年增長2.2%,其中符合居家不外出需要的商品銷情格外強勁。

對於2021財年,迅銷預期營運數據將回升,料全年收益為2.2萬億元,經營溢利為2,450億元,純利1,650億元,全年派息同樣為480元。迅銷又預計,將於2021年8月底前進一步擴大全球門店網絡至3,725間門店。

資料來源:香港經濟日報 (2020年10月16日)

5、內衣配件商生意挫 冀建平台覓出路 第3代加入蒐集數據 為行業帶來改變

雖然胸圍可說是女性的必需品,但銷情受疫情拖累,整個產業鏈亦不能獨善其身。生產內衣配件的鴻漢科技生意只剩3成,營運總監張穗龍坦言位於生產鏈底層,欠主導權,難以輕易轉身。

鴻漢科技由張穗龍的父親創立,生產內衣配件多年,包括肩帶、鋼圈等,唯獨不包括蕾絲。他解釋,蕾絲等與布類相關的生產,需要大量資金購買機器;生產周轉期更長達18個月,作為小型企業,難以承受此風險。

屬生產鏈底層 難輕易轉身

另一方面,即使該企基本上包辦生產內衣的所有配件,但他堅持不踏足縫紉內衣成品。張穗龍表示:「由父親成立公司以來,與各客戶建立穩定及良好關係。若決定生產內衣成品,客人則會成為同行競爭對手。」正正是因為這個考慮,奠定鴻漢科技的發展路向。

不過,面對市場日益嚴峻的挑戰,鴻漢科技一直在生產鏈底層,難憑一己之力轉身。張穗龍透露,在新冠肺炎疫情期間,零售市道低迷,拖累生產定單只剩下3成。業內不少零售商未轉型,仍堅守實體門市,導致在疫情下損失更慘重。

他亦指,由於在產業鏈上欠缺主導權,不時亦被客戶拖着走。現時小批量、急單的情況愈來愈常見。零售商一開始會以「款多量少」的方式落單,測試市場反應;及後再集中某些款式加急單,趕在該季度內出貨。此情況與以往「款少量多」的方式截然不同,更提高了生產難度。即使內衣行業已發展多年,但張認為零售品牌仍然未掌握顧客的需求,導致不時出現更改款式的情況。他坦言:「有些時候,甚至由廠商向品牌建議生產方向。」

張穗龍的女兒張文珊亦開始踏足這行業,身為公司的第三代,希望以消費者的角度為內衣產業帶來轉變。她指:「我曾經逛了一整天,亦找不到合意的內衣,最後亦只勉強地買一件回家。」就因為是次的經歷,讓她打算開始「內衣革命」。

經平台分析 推薦合適款式

張文珊以7位數字資金,成立了「bbShadow」,在平台蒐集女性對不同品牌、款式胸圍的穿着體驗。她希望有足夠的數據後,可根據每名女性的身形體態特點,分析並推薦合適的款式,減少撞板的機會。張穗龍又補充,平台不久前才推出,現時只獲得約400組數據;惟他希望一年內可錄得過萬組數據。

作為B2B生產商,踏入直接面向消費者的領域,短期內似乎對本業毫無幫肋,但張穗龍認為:「商機或許不會即時出現,但相信平台可以為整個行業帶來益處。」同時,張文珊又相信數據分析亦有助零售品牌,更準確理解消費者的需求及喜好,亦可成為行業及該企的一條新出路。

資料來源:香港經濟日報 (2020年10月14日)

6、大摩升互太紡織目標 料上半財年收入好過預期

摩根士丹利發表報告,認為互太紡織關鍵品牌客戶訂單正在逐步恢復,將令2021財年上半年收入好過預期。

該行指,互太紡織受惠Nike等品牌訂單恢復,八月和九月產能利用率回升到約80%,把2021財年上半年收入預測由原先按年下跌34%,調整至下跌20%。

大摩繼續關注互太紡織2021財年下半年訂單強度的持續性,料收入按年升22%。

該行預計短期股價將會表現積極,上調目標價至4.5元,維持「與大市同步」評級。

資料來源:信報財經 (2020年10月15日)

7、Fung Business Intelligence: Dual Circulation Series Issue 1 & 2

Issue 1: Dual Circulation Is Not Just A Buzzword

https://www.fbicgroup.com/sites/default/files/Dual_Circulation_Issue01.pdf

Issue 2: Export manufacturers turning to domestic market - When one door closes another opens

https://www.fbicgroup.com/sites/default/files/Dual_Circulation_Issue02.pdf

For more Fung Business Intelligence publications, please visit: https://www.fbicgroup.com/?q=reports

Source: www.fbicgroup.com (15 Oct 2020)

8、US, EU Fashion Brands Refused to Pay $16B in Garment Orders: Report

$16.1 billion. That's how much apparel imports flopped from April through June in the United States and from April through May in the European Union.

Given the lead times on apparel orders, the only plausible explanation for the steep decline is the failure of brands to pay for the clothing they ordered before Covid-19 seized the globe and sent whole economies into free fall, a new report from the Worker Rights Consortium and the Center for Global Workers' Rights at Penn State University claimed this week.

During that time, U.S. brands and retailers shelled out $9.7 billion less in garment deliveries than they did in the same period last year, a plunge of 49 percent, according to newly released trade data. In the EU, brands and retailers signed off on $6.5 billion less in orders than they did during those same months in 2019, a drop-off of 45 percent. (June data is not yet available for the EU.)

"It is crucial to understand that, because of the time it takes to produce and ship an order after the brand places it, decisions by brands to reduce or forego the placement of new orders with suppliers cannot explain this precipitous drop," the authors wrote. "Most new orders placed after the crisis began did not begin to arrive at U.S. ports until July. The vast bulk of the shortfall in U.S. imports through June represents the outcome of orders that brands and retailers had placed, and that suppliers had already produced or were in the process of producing, before the crisis began."

This nosedive in value has led suppliers in Cambodia, Bangladesh, India, Myanmar and Vietnam to freeze production, slash operations or go out of business entirely, leaving millions of garment workers facing reduced hours of work (and therefore reduced income), furloughs or loss of employment, the report noted.

The month of June saw an uptick in the value of apparel imports relative to May, even though the numbers still lagged far behind those of 2019. The bump, the authors wrote, reflects, "in substantial part," the impact of pressure on brands and retailers from unions and labor-rights advocates seeking redress for canceled orders, retroactive discounts and delayed deliveries and payment.

Certainly the value shortfall wasn't because of government lockdowns, the report said. While India and Honduras had strict lockdowns in March and April, Vietnam and Nicaragua did not. Bangladesh, the worst hit of the garment-producing hubs, experienced a temporary lockdown, but since garment production was largely considered an essential economic activity, any suspension of factory work or shipping was brief.

"What the data show are substantial losses in export value in countries with strict lockdowns and those without strict lockdowns, somewhat larger in the former but significant across the board," the authors said. "The data-coupled with the fact that many suppliers were positioned to catch up in May on production delayed by lockdowns in March and April-indicate that lockdowns, while having an effect, cannot explain most of the dramatic loss of value seen in data through June."

Further examination of U.S. trade data revealed that the overall slump in the value of imports stemmed not only from a decline in order volume but also a decline in prices. The months of January through June saw a net loss of $1 billion that correlated directly with falling per-unit prices, the report said.

"While unit prices for apparel tend to decline modestly year over year due to the price pressure that is ubiquitous in the region, the decline in 2020 over 2019 is vastly larger than normal and is driven by the industry's response to the pandemic," the authors wrote. "Since prices reflected in the trade data involve orders placed-and prices contractually agreed-before the pandemic's primary effects were felt in the U.S. in March, the only means through which the reductions in unit price apparent in the data could have been achieved is the imposition by brands and retailers of retroactive discounts-below the agreed contract price for the goods in question."

The findings of the report also suggest that garment workers lost close to $2 billion from April through June, based on reduced imports for the U.S. and EU markets alone.

The numbers square up with those from previous studies: An earlier report from the Clean Clothes Campaign, the apparel sector's largest alliance of labor unions and non-governmental organizations, estimated that truncated wages culminated in garment workers losing between $3.19 billion and $5.79 billion from March through May.

Source: www.sourcingjournal.com (12 Oct 2020)

9、Bankrupt JCP Closing 144 More Stores

Bankrupt J. C. Penney now plans to close 144 additional stores, bringing its total closure count this year to more than 300.

Penney’s in April identified six locations to close before its bankruptcy filing in May. The initial plan was to slash 242 stores as part of a reorganization, but now more stores are on the chopping block. Penney’s initial store closure list totaled 154 in June, with two New York City locations slated for closure a month later. With the new list of 144 rejected leases that Penney’s filed with the bankruptcy court on Thursday, the retailer will have closed 300 stores during its bankruptcy, and 306 for the year to date.

News of the additional closures comes when Penney’s is hoping to button up a sale and exit Chapter 11. It already has a nonbinding agreement with a group of first-lien lenders and its two largest landlords for the operating component of the business. Valued at $1.75 billion, the agreement in principle still needs to be finalized as an asset purchase agreement by Oct. 16. While a minority group of first-lien lenders wants to put in a bid of its own—for what portion of Penney’s assets is still unclear—questions remain over whether it would actually be able to amass the necessary funds. Penney’s for now has a sale hearing set for Nov. 2 and a confirmation hearing on its reorganization plan on Nov. 24-25, which is expected to pave the way for a Chapter 11 exit in December. That’s all presuming there are no more hiccups along the way.

At Wednesday’s court hearing as the Aurelius Capital Management-led minority first-lien lender group pushed for a chance to make a competing bid, Penney’s bankruptcy attorney Joshua Sussberg from Kirkland & Ellis noted that the company must move quickly to confirm a sale and plan of reorganization. He said vendors have generally been supportive, but that “many are waiting for a binding deal and closure to fully support, or resume supporting the company.”

Some vendors aren’t shipping goods, he added, which the retailer needs if it wants to compete during the cutthroat holiday selling season.

At the time of its filing, Penney’s operated 850 stores, and the 300 closures have now far exceed its original plan to trim 242 stores. Presuming a December exit, the store closures will give it just shy of 500 doors in operation post-bankruptcy.

Source: www.sourcingjournal.com (9 Oct 2020)

10、Uniqlo has more stores in China than Japan

The number of Uniqlo stores in China has surpassed those in Japan, reaching 767 at the end of August compared to the 764 directly run stores back home, Nikkei reported on Saturday.

Uniqlo entered the Chinese market in 2002, starting in Shanghai. Its store network has nearly doubled in five years from 387 in August 2015.

The company saw growing reliance on the Chinese economy to bring the pandemic under control, as it has added seven locations per month on average since June to branch out into the country's regional cities.

Uniqlo's parent company Fast Retailing is also accelerating its push in China, trying to build a new business model integrating e-commerce with physical stores that can be exported back to Japan.

In the business year that ended August 2019, about 20 percent of Fast Retailing's sales in China were from online shoppers, double that in Japan

"China is ahead in terms of e-commerce and payment systems," said Fast Retailing chief Tadashi Yanai. "If we can succeed in syncing e-commerce and existing stores, we can reach 2 trillion yen in sales for sure," he added.

Yanai told Nikkei that the number of stores in China can go for about 3,000 given the population of 1.3 billion, indicating further expansion plans.

Source: https://news.cgtn.com (10 Oct 2020)

11、H&M’s New Collection Follows Ellen MacArthur’s Jeans Redesign Guidelines

A strategic partner with the Ellen MacArthur Foundation, H&M bowed its first men’s collection designed following the organization’s Jeans Redesign guidelines.

Launched last year, the widely adopted guidelines are based on the minimum requirements for the durability, material health, recyclability and traceability of jeans. Determined with the input from 80 experts in the denim industry, Jeans Redesign aims to keep jeans being worn longer or remade into new jeans when consumers no longer want them. The guidelines also ensure that garment workers and the environment are safe from harmful chemicals and encourage universal tracking and tracing technology to accurately identify the material composition of the jeans for recycling.

While more than 60 companies are now developing Jeans Redesign products, H&M was an early adopter of the guidelines. The brand’s new Jeans Redesign collection, launching Thursday at HM stores and on hm.com, is one of the earliest collections developed with the sustainable framework.

For this project, H&M designer Jon Loman said the design team had the opportunity to go back and revisit the fundamentals of good jean design.

“Sustainability and circularity should be seen as the parameters that designers move within. It’s a new set of borders and limitations, if you like,” he said. “Being a designer is also about finding new opportunities and connecting more with the technical side of how a pair of jeans are made.”

The guidelines require cellulose-based fibers that must be sourced from regenerative farming, organic or transitional methods. The denim fabric used throughout H&M’s collection is made from a mix of organic cotton and up to 35 percent recycled cotton derived from post-consumer waste. Only dyes that “considerably” reduce water waste and energy consumption compared to conventional methods were used, H&M stated.

To ensure easy disassemble for end-of-life recycling, metal rivets were replaced by alternatives such as bar tacks, and H&M used threads made with Tencel fibers. Additionally, no conventional plating was used on the metal trims, thereby reducing the environmental impact.

For the collection, H&M used the Screened Chemistry method for selecting safer chemicals and low-impact finishes, which secured a green score by Jeanologia’s Environmental Impact Measurement—steps that H&M noted go beyond specific requirements set in the Jeans Redesign guideline. The collection also benefits from H&M’s “traceability layer,” which provides details like production country, supplier name, factory name and details about the facilities for most of its products.

The Jeans Redesign collection builds on the Swedish retailer’s efforts to clean up fast fashion. Last week, the company introduced Looop, an in-store, container-sized garment-to-garment recycling system that mechanically shreds castoffs into fibers, spins them into new yarn and then reknits them into new fashion. H&M was also part of a group of brands that partnered with Finnish biotech firm Infinited Fiber Company to develop a circular alternative to virgin cotton.

In terms of fashion, the Jeans Redesign collection ticks off all of the relevant demands in men’s wear. The utility-inspired collection offers three jeans—slim and straight, regular straight and relaxed—a Trucker jacket, a work jacket with three patch pockets and a classic over-shirt in a color palette of light gray, washed black, deep indigo and mid-blues. A tote bag and a trendy bucket hat round out the collection.

The collection’s retail price range is $9.99-$59.99.

“With this collection we hope that we can take another great step towards making more sustainable products,” Loman said.

Source: www.sourcingjournal.com (15 Oct 2020)

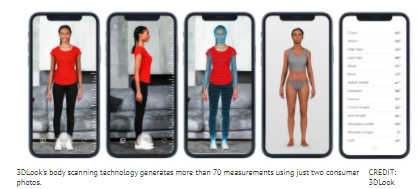

12、3DLook’s New Body Shape Analytics Software Aims to Optimize Apparel’s Fit

It’s no secret that e-commerce has been growing in recent years, and the Covid crisis has further accelerated the shift to online shopping.

But even amid new marketing strategies and point-of-purchase efficiencies, the issue of fit still persists. Buying clothing on the web is often a game of chance, and it has the potential to leave shoppers frustrated. That consternation extends to retailers, who then have to contend with mountains of returns—some of which can’t be re-sold due to damage.

Retail technology platform 3DLook aims to help brands optimize fit by arming them with actual consumer data. “Apparel companies throughout the industry have struggled with gaining customer satisfaction when it comes to creating perfectly fitting garments, and the challenge has accelerated with the rise of e-commerce during the lockdown,” said 3DLook co-founder and chief product officer Alex Arapov.

New body shape analytics software could be the feature brands and manufacturers need to better align their products with actual shoppers, according to 3DLook. The solution, which launched Monday, augments the company’s existing size and fit recommendation software.

Apparel companies will now receive access into 3DLook’s existing consumer data set—which pinpoints more than 70 points of measurement on each individual’s body—as well as insights into how they are actually shaped. This new data set can be used to adjust grade rules to create better fitting products, while also identifying new demographic opportunities.

“Apparel brands will have visibility into not only the measurement data of their customers, but also segmented body shape data where they will have several views in their dashboard,” Whitney Cathcart, 3DLook co-founding chief strategy officer, told Sourcing Journal. These perspectives will allow brands to analyze gender, height, weight, and shape distribution by geography.

“The goal is to better understand customers’ body data to better align fit in the product development process to reduce waste,” she said, as well as enabling “more intelligence relevant to distribution to better predict inventory.”

They company’s 3D-modeling software generates data from just two front and side view photos of each shopper. 3DLook analyzed more than 100,000 unique customer profiles, identifying attributes unique to their data, and segmented body shapes based on different angles and measurements.

“We’ve spent the last couple of years working on expanding our body shape analysis of our large internal proprietary dataset,” Cathcart said, adding that 3DLook has refined its algorithms and created new datasets based on the large volume of 3D body scans it has received in recent months.

Not only can brands utilize these insights during the product development process, but they can implement 3DLook’s body shape analytics on the front end, too. The company’s consumer-facing YourFit solution, which provides size and fit recommendations to shoppers through a widget placed on a brand’s website, will help optimize the shopping experience while actively collecting more data.

“With this new feature, businesses will not only have access to body measurement data but to new reports on the shape data of their customers,” Cathcart said.

Just a few short months into the retail lockdown, 3DLook released a consumer-facing augmented reality solution that allows shoppers to virtually “try on” a garment using a 3D avatar, personalized using their measurements, for more effective online shopping.

Source: www.sourcingjournal.com (14 Oct 2020)

13、Is the Fashion Industry Ignoring Garment Workers’ ‘Deepening Crisis’?

Garment workers worldwide, who were already living from hand to mouth, are still losing out on billions of dollars in legally owed wages, and labor groups and industry stakeholders alike are growing increasingly frustrated over a lack of progress that is becoming more pronounced the longer the pandemic wears on.

On Sunday, the British Retail Consortium and the All-Party Parliamentary Group for Fashion and Textiles appealed to Home Secretary Priti Patel to take urgent action over labor exploitation in the United Kingdom, where they claim workers are being “robbed” of more than 2.1 million pounds ($2.7 million) every week, or the equivalent of 27 million pounds ($35.3 million) since a previous letter was dispatched in July.

That letter—signed by more than 90 retailers, investors, non-government organizations, Ministers of Parliament and peers at the height of ultra-fast-fashion retailer Boohoo’s “sweatshop” scandal—enumerated the necessity of a “fit to trade” licensing scheme for garment factories that would protect Britain’s workers from “forced labor, debt bondage and mistreatment, ensuring payment of National Minimum Wage, VAT, PAYE, National Insurance, holiday pay and health and safety.” It would also encourage retailers to source more of their clothing in the United Kingdom while supporting the development of an “ethical, world-leading garment manufacturing industry,” its signatories said.

But the British government has yet to deliver any “significant action” to “bring this injustice to an end, all the while garment workers are robbed of tens of millions of pounds in wages,” Helen Dickinson, chief executive officer of the British Retail Consortium, said in a statement.

The letter declared it “vital” that the Home Secretary not delay the institution of a licensing scheme, which Boohoo has also come out to support, stressing in a letter of its own to Patel in July that a “joint effort between industry and government” was necessary to reset the U.K. garment industry and “provide an incentive for retailers and brands to invest.”

“Right now, we have an opportunity to create a more ethical and sustainable fashion manufacturing industry in the U.K., providing better jobs and boosting the economy at a time when it is needed most,” said Lisa Cameron, Minister of Parliament and chair of the All-Party Parliamentary Group for Textiles & Fashion. “It is vital the Home Secretary takes action to introduce a licensing scheme for U.K. garment manufacturers and puts the rights of workers at the heart of the industry. Without urgent action thousands more people face exploitation.”

Dickinson and Cameron’s pleas came hours ahead of the start of Global Fashion Agenda’s online Copenhagen Fashion Summit, which labor advocates are criticizing for pointedly ignoring the “deepening crisis” of the garment workers whose efforts underpin the entire supply chain.

The two-day event, dubbed CFS+, they say, highlights “redesigning value” and the creation of a “more resilient” post-Covid-19 business model by bringing “industry leaders and “diverse voices” together, yet it ignores the “people who need to be heard the most” and who have suffered the economic brunt of the pandemic.

Instead, the CFS+ program is steeped with “empty, self-serving rigmarole on growth, prosperity and radical change for the future of fashion,” noted the Clean Clothes Campaign, the garment industry’s largest alliance of labor unions and non-governmental organization, in a press release Monday. Garment workers, it added, lost between $3.2 billion and $5.8 billion in the first three months of the pandemic alone.

“If CFS+ truly aims to be about sustainability as a business imperative, as the website claims, the focus of the discussion should not be just about how to create a more resilient business model, but about how to make workers more resilient during crises like the Covid-19 pandemic,” said Kalpona Akter, founder of the Bangladesh Centre for Worker Solidarity. “The global fashion industry has profited long enough from paying near-poverty wages to garment workers around the world. It is 2020 and past time for them to take responsibility for their workers, who have not only had to survive this crisis without any form of social protection, but also had their wages stopped.”

In response, Malou Wedel Bruun, communications director of Global Fashion Agenda, said she believed criticism of the CFS+ program was “premature.”

“We appreciate the importance of this topic, especially as the world continues to face the Covid-19 pandemic,” Bruun told Sourcing Journal. “However, we also believe that this criticism of the CFS+ program was premature. Similar to previous Summits, this year we include speakers from across the fashion industry, including garment workers, factory owners in Southeast Asia, academics and activist voices. And in fact, the opening interview for Day 1 of CFS+ focused on the conditions of women working in the garment industry in Bangladesh.”

“We hope and believe that the Clean Clothes Campaign will have another perspective on CFS+ after watching the two days of content,” she added.

Advocates say brands and retailers need to do more beyond honoring prior garment orders placed before the Covid-19 crisis. Bestseller, H&M, Nike and “all the other participants and associates” of the Copenhagen Fashion Summit and Global Fashion Agenda must also agree to a plan for assuring wages and severance for the workers who make their clothes.

The Clean Clothes Campaign wants to rally consumers and “others who care about the workers who make our clothes” to remind CEOs like H&M’s Helena Helmersson, who will be hosting an “impact conversation” at CFS+ Tuesday, that committing to a wage assurance—which guarantees that all workers making and handling clothes in their supply chains receive the full wages they are owed in accordance with labor laws and international standards—is the “most impactful” point they can make.

“We were shocked to find out how brands behaved at the beginning of the pandemic: cancelling orders, of which some had already been finished, and refusing to pay for them,” said Ineke Zeldenrust, international coordinator at the Clean Clothes Campaign. “H&M has committed to pay for all orders. However, paying for those orders is far from enough. We’re still receiving reports from unions around the world of rights violations.” Factory owners, employees have complained, have been using the pandemic as an excuse to break up union activity, lay off workers unfairly or avoid paying maternity benefits.

David Sävman, head of production at H&M Group, told Sourcing Journal that while the company is “well aware of the shared challenges the fashion industry faces,” particularly during the pandemic, it has a responsibility to “take actions that contribute to systemic change that will stand the test of time.”

“There is an evident need for structural change in some textile-producing countries, in particular those with weak social protection systems,” Sävman said. “Therefore, advised by the International Labour Organization and global trade unions, we will continue our work to support social protection, freedom of association and stable processes where wage negotiations between the parties on the labor market can take place.”

H&M, he noted, will continue to be a “fair and responsible buyer—including committing to contractual agreements—as well as collaborate with trade unions and other industry actors to create change, for example within the ILO Call to Action.”

“And regardless of whether there is a pandemic or not, we always require and follow up that all of our suppliers pay their employees at least legally mandated minimum wages,” Sävman added.

But Zeldenrust says that brands, including H&M, “show absolutely no sign of solidarity with the workers who have provided them with profits through the years.” Before the pandemic, activists accused the retailer of failing to deliver on its 2013 commitment to ensure a fair living wage for 850,000 garment workers by 2018. They further claim that H&M is involved in several wage theft cases that the company has blamed on Covid-19.

“In fact, the opposite is true,” she said. “There is no hesitation to push the severest effects of the crisis to the workers at the bottom of the supply chain while people like Helena Helmersson hobnob at fashion summits.

Source: www.sourcingjournal.com (13 Oct 2020)

14、Can Fashion Fix Itself?

The problems facing this industry have gone mainstream.

A quick survey across the September issues, typically fashion-focused editions pointing to the "in" silhouette or the hottest trends, quickly brought a different picture to light. The American Vogue cover was titled, "Hope, a Special Issue," "100 voices on the future of fashion." British Vogue's lead story was, "What Will It Really Take to Fix Fashion?" Vanessa Friedman in the New York Times interviewed celebrity designers on "What's next?" Every question and opinion was about tipping points, making the world a better place, the glut-of-stuff, and words like "redefine," "reimagine," "reinvent" and "relevance."

It shows an industry in crisis.

September was a busy month for me as well. To re-create our annual Sourcing Summit as a virtual event this year, I logged more than 30 hours of prep calls with our 60-plus speakers. With so much at stake, we wanted to fine-tune discussions to maximize value and learning for our audience.

From the headlines to these conversations with those of you on the frontlines, two things became clear: fashion is in crisis and fashion may not be able to fix itself. It will require outside voices and new learnings to set priorities for growth and profitability. The cover story today is this: "What Got Us Here, Won't Get Us There."

Too often on these calls, I did not hear confidence. Fashion must become bold once again, to rediscover its swagger and escape being an industry of "same old, same old." Our definition of creativity is too narrow. Creativity is not only for the design suite anymore, it must be spread across the entire organization. Innovation and experimentation are about more than product and materials and apps. Today, creativity must be found upstream, in the processes that deliver the goods. But lately, executives have been too afraid to take the risk. Instead, they're beholden to The Street, chasing quick gains, or VC firms looking for online metrics.

The lack of confidence also stems from a "who can you trust?" mentality borne out of an extremely fragmented industry. The pandemic has only further ruptured this ecosystem, and trust between vendors and suppliers is now more frayed than ever. The industry is adversarial, and the term 'partnership' rings more hollow than ever. To restore confidence, we must elevate collaboration and unity as our top priority. New faces, new voices and new approaches to creativity will lead us to a truly different and better business. This will not be easy.

The challenge is made even more difficult because the timeline for reinvention has also been revised. Our evolution cannot be incremental when the pace of change waits for no one. Five-year plans that are now four or three are not enough. Further, were these plans created for yesterday's battle or tomorrow's? The last war or the next one? A completely retooled approach to how we run our companies must happen-and happen now. Covid will be blamed for many problems, but we must not forget that this industry has been suffering for years.

We need to look for the green shoots, the new seeds of opportunity. They need to be planted now, in crisis, and they are our hope. Toyota, Zara, Apple and Tesla were all green shoots that began or pivoted in crisis. It is now fashion's turn to go green, to go digital and to accelerate the future we all want and need.

Here are our headlines and buzzwords today: US-China trade wars, Xinjiang cotton, sustainability, traceability, inventory optimization, trade finance, demand planning, material innovation, social responsibility, fulfillment…each of these supply-chain issues have upside potential. The old formulas of more doors, store comps and more inventory just don't work anymore.

Here's what I'm seeing instead.

· Nike, PVH and Todd Snyder re-evaluated their wholesale relationships with traditional department stores

· H&M offers their best-in-class sustainability factory base for pre-competitive collaboration in Treadler.

· Crocs is early adopter of digital product development

· Lululemon-acquiring Mirror-stayed true to its core customer and vision. Expanding the scope of its offering but not sacrificing its DNA and authenticity.

· Foot Locker invests in Carbon38 and GOAT.

Simply generating more demand will not solve fashion's problems. Another runway show, influencer campaign, special drop or glossy ad won't foster systemic change. Our businesses, to be relevant, must unlock working capital and find efficiencies in all aspects of the process, beyond just design and sales.

According to McKinsey, the 10 top retailers in the world account for 90 percent of the industry profit. This problem is not going away soon.

The new breed of consumer already shops their values, and not status, flash and indulgence. Those who are constrained financially are now selective in how and where they shop. Certain categories are selling, but not everyone can become a fleece or yoga pant manufacturer, get into the PPE business, out-ship Amazon or out-price Walmart.

For one of the largest industries in the world, the pie is not growing. The urgent questions are: What do you stand for? Why are you essential? People need value and beauty and a better world. Is that how you define your brand?

Ray Dalio, founder of Bridgewater, the world's largest hedge fund, sees three to seven years of recovery ahead. He says we are in the "era of lost growth." In this reality, how does fashion find its footing? How does fashion remain relevant and sustainable? Unfortunately, the analysts tell us that inventory is not coming down fast enough, that promotions are still too prominent, sourcing risks too high and online investment too slow.

What are the new metrics of success? First, it is collaboration and unity as an industry-wide culture. Second, it is community with our consumers to contribute to a better world through sustainable fashion. Third, an accelerated commitment to change. And, fourth, it is confidence that fashion can fix itself-with new learnings from outsiders, but brought to life as only insiders know how.

Ralph Lauren recently said, "Living right now, the world is not frivolous. So, fashion must find a way to be more meaningful, more purposeful, to add comfort and beauty to our lives."

Can fashion fix itself? The answer is: it must. There's too much to fight for.

Source: www.sourcingjournal.com (12 Oct 2020)