2021年8月20日

行業報導 - 2021年8月20日

1、港人入境深圳鬆綁 僅集中隔離七日

(星島日報報道)內地關口有鬆綁的迹象,深圳市口岸辦昨日宣布,由即日起符合深圳居家隔離條件者,入境後可申請「7+7+7」隔離醫學觀察和健康監測,其餘人士的檢疫期則獲縮短至十四天。旅遊業立法會議員姚思榮形容做法令通關現希望,但措施現階段僅吸引商務或探親客;呼吸系統科專家則認為兩地疫情放緩,目前適合放寬與內地的通關措施。

深圳市口岸辦昨日宣布,由即日起,從香港入境深圳的普通旅客,若持有二十四小時內的核酸檢測陰性結果紙本報告,入境後只需接受十四天隔離醫學觀察,以及七天居家健康監測。另外,若在深圳具備居家隔離條件的人士,可以改為集中隔離、居家隔離及居家健康監測各七天,即「7+7+7」隔離醫學觀察和健康監測。

按舊有安排,若在深圳並沒有居所,需在同一酒店內隔離十四天。換言之,集中隔離期將大幅縮短至七天,同時亦有機會將部分隔離期轉移至居家檢疫。姚思榮形容做法令通關現希望,他直言早前內地對通關未見有「鬆口」的迹象,而是次的放寬,若能證明本港未有將個案帶入內地,將有助證明本港的疫情穩定,有助推進措施至內地其他省市,更甚是推進通關的進度。

雖然深圳放寬自香港入境防疫措施,但姚思榮估計做法將吸引商務客或探親客,「始終仍需檢疫,相信未必有人會付出兩星期時間檢疫前往內地旅遊。」他相信,是次放能協助部分港人,親身前往內地辦理一些必要業務。

呼吸系統科專科醫生梁子超表示,現時內地與香港的疫情大致平穩,現階段放寬香港入境防疫措施,相信並不會對社會造成威脅。他形容,現階段屬逐步調整措施,但要做到真正通關,相信要本港能防止所有外防輸入的漏洞,加上內地早前經歷南京祿口機場爆疫一事後,相信對航空入境有其他考慮。

另外,食衞局前日宣布由本周五凌晨零時起,收緊曾逗留中風險地區的抵港人士的登機、檢疫及檢測要求。相關人士即使持有認可疫苗接種記錄,以及血清抗體測試陽性結果,其在指定檢疫酒店的強制檢疫期最多只可縮減至十四天,代表再不能以血清抗體測試陽性結果進一步縮減檢疫期。

局方昨日進一步交代指,原定由昨日起在機場為抵港人士提供自費血清抗體測試服務的第二階段安排暫時亦不會推行。

資料來源:星島日報 (2021年8月19日)

2、亞洲疫情反彈恐推升美通脹 全球供應鏈堵塞 憂礙聖誕來貨

Delta變種病毒擴散令曾是抗疫模範生的亞洲地區疫情急速升溫,區內多個國家的工廠和港口陷入混亂,導致全球供應鏈進一步堵塞,意味中國工業生產者出廠價格或美國消費物價的漲勢可能並非暫時性,而且年底的聖誕旺季可能面對貨物供應問題。

出口在疫情保護了亞洲區內貿易主導的經濟體,並有望帶頭推動更廣泛的復甦。根據聯合國估計,全球大約42%的出口來自亞洲,而世界貿易組織(WTO)曾預測,亞洲今年將引領全球貨物貿易增長8%。

40呎貨櫃運費勁飆3.5倍

然而,全球第三最繁忙的貨櫃港口、中國深圳的鹽田港最近因為疫情而需要局部關閉,至於亞洲受災最嚴重的東南亞,電子、服裝和其他許多產品都因為抗疫封鎖措施而停止生產,但亞洲物流問題的影響可能會晚些才展現,例如美國洛杉磯或荷蘭鹿特丹等港口貨流出現延誤,以及消費者需要支付更高的價格。

對受新冠肺炎影響折磨一年多的出口商來說,這肯定是雪上加霜。自去年3月爆疫以來,貨櫃箱短缺令航運價格飆升,航運業顧問公司Drewry的世界貨櫃指數顯示,截至8月12日,40呎貨櫃的現貨運價為9421.48美元(約7.35萬港元),比去年同期高出差不多3.5倍。

法國外貿銀行(Natixis)估計,雖然印尼、馬來西亞、菲律賓、越南和泰國的出口合共只佔全球出口總額的5.7%,但它們對美國和中國等更大經濟體造成的影響異常巨大,特別是在電子產品方面。中國從這五個國家進口38%的數據處理機和29%的電訊設備,而美國五成的半導體設備都是來自這幾個東南亞國家。

越南南部大量廠房停工

為了降低出口所受的衝擊,越南政府採取極端措施,下令製造商允許工人在工廠過夜,但情況不見好轉,反而愈來愈糟,當地一名製造商指出,整個國家的供應鏈都受到嚴重打擊,在疫情最嚴重的南部,大部分工廠已經停工,而疫情較輕的北部也有不少工廠關門。

摩根大通等大行的經濟師已經下調了全球及亞洲的增長預測,其中一個原因是亞洲國家疫苗接種率低,例如越南完全接種疫苗的人口比例持續徘徊在約1%低水平。

雖然彭博經濟的nowcast數據顯示全球經濟本季度將加速增長,但僅中國的Delta疫情就影響到佔其國內生產總值(GDP)三分之一以上的產業。

有內地製造業高層表示,去年疫情高峰時還認為一切都是暫時性,但現在看來短期內情況都不會有重大轉變。

資料來源:信報財經 (2021年8月16日)

3、貿發局籲港商借助大灣區拓內銷 把握國家支持 配合「雙循環」戰略

「粵港澳大灣區」目標是打造國際一流灣區,其中的戰略重點包括,支持香港、澳門融入國家發展大局。香港貿易發展局副總裁劉會平呼籲,港商應把握好國家支持大灣區發展的機遇,以大灣區為試點,順勢開拓內銷市場。他指出,香港一向是內地連接海外的雙向樞紐(two-way hub),配合國家「雙循環」戰略,香港聯絡人的角色有望更吃香。

劉會平稱,國家「十四五」規劃擬推動服務業轉型和國內消費升級,將為港商帶來機會。香港不僅在專業服務方面具優勢,香港品牌在食品健康、創意產業、環保等方面亦有一定賣點,要把握好今次機遇,積極開拓內銷市場,大灣區正好可作為試點。

五地開設GoGBA服務站

他提到,新冠疫情帶來兩方面影響。其一,港商過往倚重的歐美市場受到較大衝擊,開拓內地市場變得更加有必要;其二,包括香港特區政府在內,各地政府積極推出經濟紓困政策,支撐商界渡過難關,對業界而言是拓展新市場、開發新產品的好時機。

為協助港商開拓大灣區市場,貿發局今年6月推出GoGBA一站式平台,提供大灣區各種營商資訊,並舉辦交流活動、研討會等。

同時,貿發局在深圳辦事處增設「香港貿發局大灣區服務中心」,並與廣東省有關部門合作,在深圳前海、廣州南沙、珠海橫琴、東莞及中山開設「GoGBA港商服務站」,提供必要的線下服務。

中外聯絡人角色更吃香

劉會平坦言,內地市場競爭格外激烈,像過往僅以香港品牌為賣點已不足夠,港商必須提供附加價值,例如述說一些特別的故事、或者具獨特的創意、專注環保及健康等。營銷方式也要跟隨內地消費者習慣,學習如何利用老闆帶貨、網紅(KOL)營銷等手段。貿發局將因應業界所需,舉辦交流、分享活動,協助港商解決實際操作上遇到的問題。

香港是粵港澳大灣區內最國際化的城市,一直以來扮演着連接內地與海外的中間人角色,外界一直擔心,隨着外資和外商可直接與內地建立聯繫,香港這一角色將逐漸黯淡。劉會平則認為,港商不只是做中間人,更是合作夥伴,一起把海外的品牌、高質素的產品和服務引入內地;港商多年來已建立起的國際網絡,累積的國際經驗,這優勢內地商家未必可在短期內追上。他直言:「我不認為香港作為聯絡人的角色會消失,反而會很吃香。」

貿發局的GoGBA平台包含繁簡體中文及英語,劉會平表示,不止港商尋求貿發局協助開拓大灣區,外國企業也很積極徵詢如何經香港開拓大灣區業務。除了少數大型外企選擇自行進入內地市場,多數海外公司仍然樂於經香港接入內地,或是在香港先成立辦公室,可見他們續依賴香港。與此同時,香港向來是雙向樞紐,內地企業走向海外,香港服務業有很多可以幫忙的地方。香港可說是一條橋樑,既能幫助港商,也幫助其他人。

T-box免費幫企業升級轉型

香港貿易發展局除了利用GoGBA平台支援港商開拓大灣區,還有自去年4月開始的T-box升級轉型計劃及「寄售易」(ConsignEasy)服務。貿發局副總裁劉會平表示,T-box為企業提供為期3個月的免費支援,協助中小企達成升級轉型目標,近期不少參加計劃的企業皆瞄準大灣區。

貿發局7月初曾舉辦「T-box走進大灣區系列:內銷策略及渠道」小組研討會,邀請了14位從事不同行業的香港中小企代表,分享對內銷市場的看法,以及拓展時遇到的瓶頸,並安排貿發局中國內地總代表鍾永喜及華南首席代表吳文慧等專業團隊解答疑難,讓中小企把握恢復通關前的時間,做好拓展大灣區的準備工作。

寄售易做試點無後顧之憂

「寄售易」則為在內地未設立公司、亦無合作夥伴的港商,提供一個試水內銷市場的機會。企業把產品交給貿發局旗下「香港.設計廊」,由後者透過其內地網絡銷售和推廣,一併處理進口報關、貨品配送、銷售營運、稅款繳納、結算收款等一系列複雜事務。當港商透過「寄售易」試點後,對開拓內銷市場有了信心,可轉而建立自己的網絡,正式準備進軍內地市場。

貿發局的GoGBA平台,除了官方網站,還特別開通了「灣區經貿通」微信小程序,當中不但可搜索大灣區內各城市和行業的政策、資助及優惠、商務支援、活動及培訓等最新資訊,亦可啟動計算於內地停留日數的工具,以便調整內地的工作安排,應對單一納稅年度累計居住滿183天便須繳納個人所得稅的要求。小程序內同時設有互動地圖、跨境交通等服務選項,方便在大灣區內隨時查詢。

資料來源:信報財經 (2021年8月16日)

4、薛永恒參觀紡織研發中心 冀科研推動業界「再工業化」

創科局局長薛永恒今日(13日)參觀香港紡織及成衣研發中心,其間了解多個推動紡織業創新及可持續發展的紡織物循環再造和高性能紡織技術,並期望中心可帶動香港紡織業的「再工業化」。

薛永恒表示,香港紡織及成衣業是全球市場的重要持份者,喜見研發中心在產業鏈不同環節以科研提升競爭力,為業界開發嶄新物料和先進生產技術,透過研發及技術轉移,使紡織及成衣業邁向高增值生產及服務。

薛永恒又鼓勵研發中心繼續與業界同行共創,促進研發成果商品化,令業界可以應用更多新技術並開拓新的發展空間,帶動香港紡織業的「再工業化」。

資料來源:星島日報 (2021年8月13日)

5、快時尚品牌被指縱容污染非洲河

國際水見證機構(WWI)周二發表報告指出,Zara、H&M和ASOS等國際快時尚(fast fashion)品牌的衣料供應商,在非洲國家坦桑尼亞和萊索托的作業污染當地河流,河水被染色,水中鹼值變得與漂白水一樣。

撰寫報告的WWI總監赫普沃斯(Nick Hepworth)直言,這些國際品牌原本可以迫使合約製造商改善生產過程,但迄今對於制止眼前非洲衣料廠盛行的污染和囤積水資源的情況着力甚少。他補充,換一個角度說,這些快時尚產業可以成為改革力量,但必須由品牌商和投資者領頭。

H&M確認布料來源 Zara拒評

報告點名約50個國際品牌的衣料源頭在非洲國家,不過未有指出直接與污染有關的供應鏈企業,僅稱這情況突顯非洲的廉價勞動力與稅務優惠吸引愈來愈多國際品牌購買當地衣料,卻變相毒害了河川。

研究人員在萊索托發現一條河被牛仔褲的藍色染料污染。報告表示,從坦桑尼亞三蘭港(Dar es Salaam)一家織品廠附近的姆辛巴濟河(Msimbazi)採集河水樣本,檢驗出pH值12,鹼性程度與漂白水相同,而當地人使用姆辛巴濟河的河水來梳洗和灌溉。

Zara對此沒有置評,ASOS和H&M則確認其布料來源地是非洲,但表示它們的產品主張可持續性和重視水資源危機。

資料來源:信報財經 (2021年8月18日)

6、Vietnam factories rethink 'sleepover' approach to stopping COVID

Country's virus woes pose risks for global supplies of sneakers and smartphones

HO CHI MINH CITY -- The warehouse manager at Truong Thanh Furniture near Ho Chi Minh City did her best to avoid the virus. For weeks, she worked and slept at the factory alongside 200 colleagues, with few people allowed in or out.

Truong Thanh Furniture was complying with a government order for factories to keep workers on-site or else shut down.

It provided meals and blankets, but the measures were not enough; the virus slipped past the company's defenses and infected the manager.

Truong Thanh Executive Chairman Mai Huu Tin told Nikkei Asia he believes the woman caught the virus from a delivery driver. It is not the only company that has detected cases despite taking strict safety measures. Now dozens of businesses are moving away from the sleep-at-work model introduced to prevent COVID-19 from disrupting the country's vital manufacturing sector, which churns out everything from shoes to smartphones for the global market.

Thousands of Vietnamese have spent the past month living at work, away from their families. The situation has taken a heavy toll on mental health and corporate balance sheets. Now some companies are questioning the approach and asking the government for vaccines and "safe zones" where workers can live near plants, and for it to take other measures.

"Owners cannot control infection 100% because to continue operating, factories still need to get supplies from outside," said Tin, who paused operations at one factory but is continuing the sleepovers at others. "Facilities there are not meant for human living."

While electronics manufacturers such as Apple supplier GoerTek and Samsung are using the sleepover model, not everyone finds it feasible.

Taiwan's Pou Chen, the world's No. 1 contract shoemaker, suspended production at its biggest site in Vietnam, near Ho Chi Minh City, from July 14, citing difficulty sheltering 56,000 employees on-site.

"We do see pressure on our short-term production capacity, and we do expect the financial impacts in July and August," the company told Nikkei Asia. "For the longer term, we will try to be more flexible and ask our other production sites to help with some production, too."

One manufacturer said it has shelled out $100,000 to house 900 people at work, while another said costs had roughly doubled even as production fell by half. New expenditures include virus tests, laundry services, protective gear, meals and sleeping mats.

Despite the extra spending, sources say outbreaks have hit isolated plants in Binh Duong and Dong Nai, two industrial provinces next to Ho Chi Minh City.

"There are many cases where COVID cases still occur in a company," one of the sources said.

Another southern province, Tien Giang, in the farm-heavy Mekong Delta, found 400 cases at six companies hosting sleepovers, the state Voice of Vietnam reported on Aug. 8. These included seafood, fruit and steel businesses.

"Vaccines are the only way out," said KJ Ung, Vietnam managing director of panel maker First Solar, which is having staff live on a site the size of 60 soccer fields. "Global supply chains will be affected if we continue this way.

"Employees' psychology and all those mental health issues have to be taken care of as well."

A number of companies are throwing in the towel. The Dong Nai Industrial Zones Authority on Tuesday published a list of dozens requesting to end the sleepovers, from Nippon Paint to Hansoll Textile. It is not clear what the next step might be.

On Monday, a post on the Ho Chi Minh City website outlined alternatives to on-site living arrangements, such as company-controlled transport to and from work, or setting up designated safe areas for workers to stay.

The latter option, however, could require finding land. While northern factories have space to isolate infected workers or separate crews, the south is more crowded, said Nguyen Thanh Binh, a director at the Vietnam Chamber of Commerce & Industry.

"An inch of ground is equivalent to an inch of gold," he told Nikkei.

The hit to supply chains from factory disruptions will be large, according to Natixis economist Trinh Nguyen. She wrote in an Aug. 12 report that the global shoe and textile sectors would be affected, with some impact on electronics as well, given Vietnam's "staggering share of mobile phone exports" from Southeast Asia. The communist country's overall exports ticked down 0.8% from June to July, while virus cases exceed 300,000. Like much of the region, Vietnam is struggling to flatten the curve of infections, though it is hindered by a contagious variant and low vaccination rate.

Besides disease, continuing to live at factories poses damage and even fire risks, Tin, the furniture executive, said.

"Safe zones for workers to stay after work would help," he said, "especially if they can stay with their families or friends."

Vietnam's apparel exports take a hit as manufacturing stops: TexPro19

Apparel exports from Vietnam have taken an unexpected hit and are likely to decline further in the second half of this year due to the rising cases of COVID-19 in the country. Exports rose consistently in the first quarter due to the efforts of industry stakeholders, implementation of sustainable strategies, vaccination drives and improved product quality.

Vietnam’s monthly average for apparel exports was $2.42 billion in the last quarter of 2020. It increased slightly by 4.05 per cent to a monthly average of $2.51 billion in the first quarter of 2021 but dropped again by 15.12 per cent to a monthly average of $2.13 billion in the second quarter of 2021, according to Fibre2Fashion’s market analysis tool TexPro.

Vietnam’s apparel exports are expected to decline further by 18.45 per cent to a monthly average of $1.74 billion in the second half of 2021.

The EU-Vietnam Free Trade Agreement (EVFTA), the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the UK-Vietnam free trade agreement (UKVFTA) helped the nation to boost trade amid the pandemic. The UKVFTA that officially came into force on May 1, 2021, increased Vietnam's apparel exports to the UK as it removed almost all customs duties between the two countries.

Vietnam developed policies for low-cost manufacturing that boosted the production index. It sought new raw material suppliers from India, South Korea and European countries and reduced the dependency over China for raw materials.

The demand from western markets has been increasing from the beginning of 2021. The Vietnam Textile and Apparel Association (VITAS) developed three strategies to boost apparel exports – reviewing the changes in consumer demand in key export markets; adoption of advanced production technologies to save fossil energy, cut gas emissions and increase recycling; and investing in product development. Better compliant processes and improved human rights also drove Vietnam’s exports.

However, the country is currently dealing with the rising cases of COVID-19 and low rate of vaccinations. The new wave has suspended the textiles supply chain and forced manufacturing units to close.

VITAS has requested the government to vaccinate textiles and apparel workers on a priority basis and has asked to buy the vaccine directly from suppliers.

Source: asia.nikkei.com & www.fibre2fashion.com (19 Aug 2021)

7、Bangladesh commerce minister aims to grow US apparel exports

Bangladesh commerce minister Tipu Munshi told attendees at the 'Men's Apparel Guild in California', in Las Vegas that the Bangladesh government aims to increase the volume of garment exports to the US.

The Bangladesh commerce minister explained that his government is assessing improved standards of apparel, designs, and choice for US customers. The aim is to gain a bigger market share in a country where he says Bangladesh already sends US$7bn worth of garments each year.

According to a report published by The Daily Star, Munshi’s government has a special initiative to further increase the volume of garment exports to the US on the back of high demand.

The idea is to create data specifically for US customers and to supply apparel tailored to their specifications.

The Daily Star’s report explains Munshi was keen to point out that after the Rana Plaza building collapse in April 2013, Bangladesh has strengthened workplace safety for those working within garment factories.

The minister has invited US retailers and brands to visit Bangladesh’s apparel factories and to observe the safety and compliances in the factories, according to the report.

The announcement from the commerce minister follows the news earlier this week that Bangladesh’s apparel exporters are concerned over a rise in yarn prices on the domestic market, which is making it difficult for them to capitalise on growing garment orders from the west.

Source: www.just-style.com (13 Aug 2021)

8、US exports as of June 2021: What does it mean for global apparel?

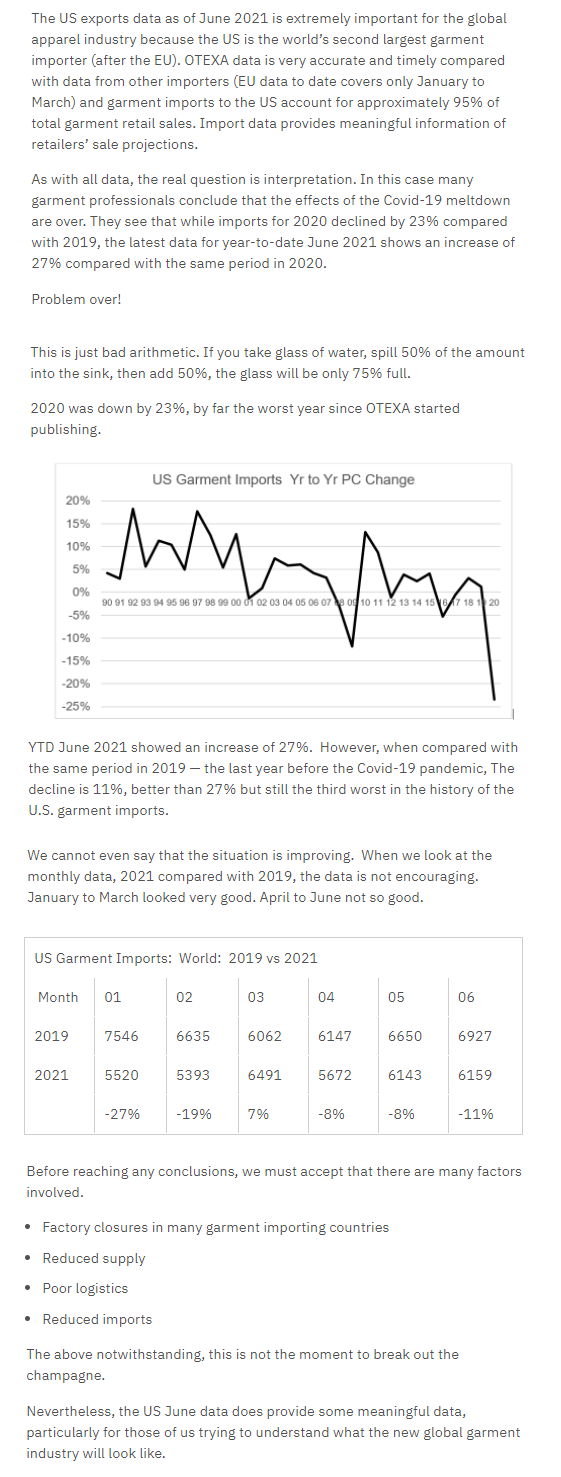

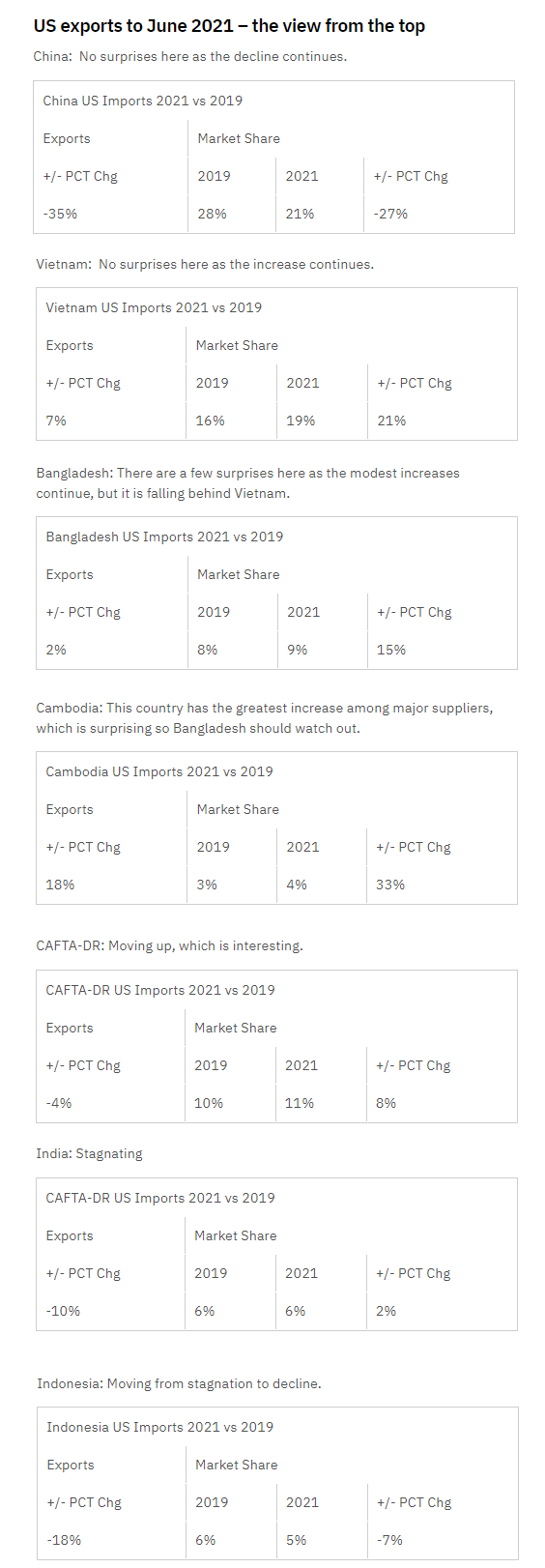

Earlier this month the US Government Office of Textiles and Apparel (OTEXA) published apparel export data as of June 2021. David Birnbaum explains what it means for the global apparel industry.

Source: www.just-style.com (19 Aug 2021)

9、HK's LFX Digital launches Air8 supply chain fintech for SME suppliers

LFX Digital, an offshoot of Hong Kong-based Li & Fung, has launched Air8, a supply chain fintech company, to serve the financing needs of small-to-medium enterprise (SME) suppliers across the consumer goods supply chain. GLP Financial Services has joined LFX as a strategic partner with a 20 per cent equity stake in the new company.

An LFX digital venture, Air8 is building an insight-based technology platform that capitalises on Li & Fung’s ecosystem with more than 115 years of supply chain experience, connecting suppliers, buyers, and funders in over 50 markets. Air8’s goal is to combine supply chain insights with financing expertise and digital technologies to channel capital to vendors. Air8’s vision is to promote sustainable financing while bridging the supply chain working capital gap, the company said in a media release.

Ed Lam, CEO of LFX, said, “No other financing provider has a deeper insight into the supply chain than Air8. We intimately understand the end-to-end supply chain and are building a digital technology platform that capitalises on those insights to make funding more readily accessible for SMEs.”

The huge trade finance gap is a global challenge, especially for suppliers in emerging economies that lack access to traditional financing programmes. Leveraging their experience from Li & Fung, the Air8 team will focus on SME suppliers in the apparel and general merchandise supply chain to help alleviate the pressure of obtaining the necessary funding to fulfil their working capital requirements.

“COVID highlighted the vulnerability of SMEs and their struggle to survive. Air8’s mission is to stabilise the supply chain by helping SMEs to better manage their working capital with optimal funding solutions,” said Spencer Fung, chairman of LFX.

Ming Mei, co-founder and CEO of GLP, added, “Our strategic partnership with Air8 extends our investment and partnership with Li & Fung into the trade finance arena. Since we joined forces with Li & Fung, we have been collaborating on both sourcing and logistics opportunities, and now with Air8, we are pleased to expand into the fund flows underpinning the supply chain to provide a more holistic solution to both customers and vendors.”

The company is developing a proprietary credit risk management model that provides financial institutions and investors an additional channel to invest in high-quality assets. In turn, Air8 will connect suppliers and buyers to a large and diversified group of funders via an end-to-end insight-based technology platform that quickly facilitates cross-border trading.

Source: www.fibre2fashion.com (18 Aug 2021)

10、Taiwan Textile Makers Showcase Covid-Friendly Innovations

Taiwan’s textile makers are serving up innovations that offer increased performance and functionality, as well as antiviral properties and sustainable inputs.

At an online streaming event hosted by the Bureau of Foreign Trade, the Taiwan Textile Federation (TTF) showcased the country’s latest product releases, which included skin-friendly masks that guard against microbacteria, polyurethane (PU) film made with recycled content and CBD-infused fabric that improves circulation and recovery. “Taiwan’s textile industry is a leader in eco-friendly textile innovation and sustainability, with continuous quality improvement,” TFF’s master of ceremonies, Angela Lu, said. “Over the years we have become the No. 1 choice of many international leading brands in sports and outdoor wear.”

“The Covid-19 pandemic has changed the way we dress and shop,” she added. “To keep one step ahead of this new normal, many Taiwanese textile companies have strived their best to bring their innovation to the next level.”

Outdoor material manufacturer GFun Industrial Corp., which services brands like The North Face, Columbia, Nike and Adidas, touts itself as the largest laminated coating manufacturer in the country. The company’s newest membrane technology, called GRX, makes use of plastic particles that occur as waste from the manufacturing of smartphone camera lenses by Taiwanese producers. The company adds the material, which is sloughed off in the grinding process, into its PU, using the substance to coat its high-performance fabrics. Color can also be added to the fabric coating, the company said, eliminating the need to dye the fabric underneath.

Meanwhile, Taipei-based activewear supplier Eclat Textile Co., Ltd. has been focused on the development of textile masks throughout the pandemic, releasing a number of versions suited for everyday wear as well as strenuous athletic activity. The company’s polymer-based triple-layered filter mask is designed to catch fabric and dust, and is sewn with antimicrobial silver fibers, making it ideal for commuters spending considerable time in the proximity of other people. A soft inner layer with an antimicrobial coating protects the skin and eliminates odor throughout long periods of wear. Other versions of the masks include nose guards, adjustable ear loops, durable water repellant (DWR) treatment, and perforations for increased breathability during sport.

Also made to guard against the spread of illness, a daily protective jacket with eco-water-repellant HeiQ Viroblock technology was highlighted by Ruentex Industries Co., Ltd. The company spoke to the hooded zip-up garment’s protective qualities, which include a microbe and virus-blocking coating, along with a built-in face shield. The company’s TanaCare CBD-infused leggings and pillowcases, by contrast, are infused with cannabis-derived oil, which helps reduce inflammation, promotes circulation, and supports the skin’s healing process. The pillowcases, which are finished with a CBD coating, are made to promote restful sleep, the company added.

Performance fabrics remain important as consumers continue to spend ample time outdoors and engaging in athletic activity. Sunny Special Dyeing and Finishing Co., Ltd.’s Eco Pro line of yarns is made with recycled polymer materials like RPET sourced from plastic waste, providing water resistance for performance fabrics, the company said. According to the manufacturer, the supple textiles also hold up to repeated washing, making them suitable for use in the service industry and medical field. The company’s Solapel coating can be applied to enhance water repellence, while simultaneously limiting the release of fluorocarbons into waterways during washing. The PFC-free coating remains at least 70-percent efficient after being washed more than 120 times, the company added.

Finally, Tex-Ray International presented an energy-saving CO2 reduction technology dubbed Eco HD Print that allows colors to bond better on fabrics. The water-based ink transfers at low temperatures, the company said, saving energy and preserving the integrity of fiber filaments. The ink can provide sharp-lined patterns and a soft hand-feel on performance garments like leggings and bra tops, and unlike oil-based inks, does not release harmful chemicals into waterways during the production and washing process.

Source: sourcingjournal.com (19 Aug 2021)