2021.02.26

INDUSTRY NEWS - 2021.02.26

1、3月起由香港入境廣東 只接受鼻咽拭子核酸採樣證明

深圳市人民政府口岸辦公室今日(24日)表示,經粵港兩地政府協商,自3月1日起,由香港入境廣東人員,所持新冠肺炎病毒核酸檢測報告,採樣方式必須為鼻咽拭子或鼻腔咽喉合併拭子。換言之,如是深喉唾液測試不符要求。

深圳:證明上未註明採樣方式會被送回港

深圳當局表示,如通關時出示的核酸檢測報告,未採取上述採樣方式或未註明採樣方式,將不予認可作為有效的通關證明,並安排返回香港,提醒市民應前往粵港兩地政府認可的指定醫學檢測機構,接受核酸檢測,並須獲取符合要求的核酸檢測報告。

資料來源:香港01 (2021年2月24日)

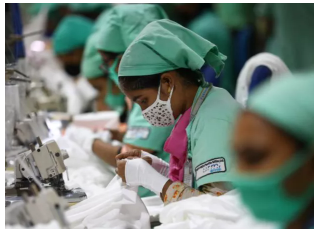

2、孟加拉制衣業壓力山大:歐美零售商削減訂單,工廠在為生存而戰

據路透社報導,歐洲和美國的服裝零售商坐擁過剩庫存,正在削減春季訂單。採購代理商面臨著延遲付款,位於孟加拉的服裝廠處於停產狀態。

全球服裝業在艱難的2020年步履蹣跚,新一輪的新冠封鎖和參差不齊的國家疫苗推廣讓其復蘇的希望破滅。一些主要的零售商仍在為去年的衣服發愁,往常這些衣服在平時清倉大拍賣時就已經賣光了。英國連鎖店Primark對路透表示,該公司在2020年春夏庫存價值約為1.5億英鎊(約13.3億元人民幣),秋冬庫存則為2億英鎊(約17.72億元人民幣)。

為了表明積壓的規模,麥肯錫(McKinsey)諮詢公司表示,全球商店和倉庫中未售出的服裝價值在1400億至1600億歐元(約1.24萬億元至1.41萬億元)之間,是正常水準的兩倍多。英國的瑪莎百貨(Marks & Spencer)和德國的雨果博斯(Hugo Boss)表示,他們今年春季系列的訂單比往年要少。

薩克斯第五大道精品百貨(Saks Fifth Avenue)前總裁Ron Frasch表示,零售商們正在保持較小的銷量和緊張的交貨期。他現在是私募股權公司Castanea Partners的運營合夥人,該公司與許多服裝品牌合作。Frasch說:“現在大部分品牌的出貨量都非常緊張,代理人也非常緊張。我想大家的採購都非常保守。我知道很多人都遲遲沒有付款。這是肯定的。”

總部位於香港的採購代理公司利豐(Li & Fung)向路透表示,一些零售商曾要求延遲付款,但拒絕提供細節。利豐在50個國家為包括全球零售商在內的零售商管理超過1萬家工廠。

因此,痛苦流向了主要的服裝製造中心,如孟加拉,這些國家的經濟依賴於紡織品出口。工廠正在努力維持運營。

孟加拉服裝製造商和出口商協會調查的50家工廠表示,由於歐洲大部分地區聖誕前的封鎖,以及1月份的另一場封鎖,對他們的業務造成了嚴重打擊,它們本季度接到的訂單比往年減少了30%。位於孟加拉首都達卡的工廠老闆Shahidullah Azim說:“訂單通常會提前三個月到達。但3月份沒有訂單。”他的客戶包括北美和歐洲零售商。

他說:“我們正在以25%的產能運行。我有一些訂單,可以讓工廠運行到2月份。在那之後,我不知道我們的未來會怎樣。很難說我們將如何生存。”

Miran Ali是亞洲六個國家製造商聯盟Star Network的代表,他在孟加拉擁有四家工廠,也面臨著類似的問題。Miran Ali在首都達卡告訴路透社記者:“在這個時間點上,原本我們的生產訂單至少在3月份之前應該是完全滿的,秋冬季的訂單也已經開始。而現在縱觀全域,這來得很慢。”

達卡另一家為全球零售商生產服裝的工廠老闆Asif Ashraf說,調整起來很艱難。“我們已經生產出了面料,我們準備縫製服裝,但他們卻說訂單被擱置了。”

紡織品回收公司Parker Lane Group告訴路透社記者,由於門店關閉可能持續到夏季,一些零售商在下新訂單之前,正試圖盡可能多地出售多餘庫存。一位首席執行官Raffy Kassadjian表示,他的企業從平均每月處理150萬件過剩服裝到1月份超過400萬件,這是其有史以來最繁忙的一個月。

根據歐睿資訊諮詢公司(Euromonitor)的資料,去年服裝行業形勢嚴峻,銷售額較2019年下滑了約17%。未來是不確定的。對2021年的估計從麥肯錫的銷售下降15%的悲觀預測到Euromonitor的恢復11%都有。

那麼有沒有亮點呢?疫情封鎖期間的睡衣熱潮正在提供一些小的緩解。瑪莎百貨首席執行官Steve Rowe說:“如果你想知道偉大的英國公眾在做什麼——他們又開始穿睡衣了。”而雨果博斯也暗示了同樣的現象,稱該公司已“精簡了我們的經典商務裝系列,擴大了休閒裝系列”。

但對一些工廠主來說,這並不是什麼安慰。達卡的Ali阿裡承認:“睡衣的需求空前高漲。但不是每個人都會做睡衣!”

資料來源:https://mp.weixin.qq.com (2021年2月16日)

3、華商涉疆強迫勞動 12日企擬停合作

日本《共同社》報道,UNIQLO母公司迅銷(06288)、索尼(Sony)及日立等12家日本大型企業,正計劃終止與涉及新疆強迫勞動的中國公司業務往來。

包括迅銷索尼日立

澳洲智庫「澳洲戰略政策研究所」(ASPI)去年發表研究報告指出,中國9個省共27間工廠都有來自新疆的維吾爾族工人,其中包括遭強制拘留者。

報告又透露,這些工廠是82家國際品牌供應鏈的一環。該報道稱,在美國、英國陸續對新疆生產的棉花等製品實施進口限制後,日本企業亦正承受壓力,但日本政府被批評因擔心觸怒中國,而對相關制裁採取消極態度。

《共同社》詢問了14家被指與涉及強迫勞動的中企合作的日本企業,除了松下(Panasonic)不予評論外,其他公司都表示會拒絕與涉嫌受益於強迫勞動的公司有業務往來。

資料來源:信報財經 (2021年2月23日)

4、中小企冀延 「百分百擔保」還款期支援 商界:政策措施雖正確 惟執行遇困難

本港面對經濟不景,不少中小企期望,預算案可延長「百分百擔保特惠貸款」的還款期,支援中小企現金流。

香港中小企促進聯會會長林國雄認為,支援本地經濟發展尤為重要,皆因疫情之後恢復遊客量須一段時間。他稱,政府過去的政策和措施方向正確,並列舉3項措施,惟中小企實際執行時遇困難。

1.中小企市場推廣基金:他認為幫助進軍海外市場是好事,但對能力和資金較細的小型企業而言,作用不大。他舉例,「(本地)賣魚蛋(小店)做不到」便難以參加內地和海外展覽,開拓新市場。

2.粵港澳大灣區青年創業資助計劃:他認為有助支援創業人士,但要創業時,未必有能力和資金先北上發展。

3.遙距營商計劃(D-biz):他認為原意發展綫上業務是好,設有專責電腦部門的中小企少有問題,但較小規模的中小企沒有相關部門,執行時要另找員工負責,招聘有相關技能的新員工又加重負擔。

林國雄希望政府進行諮詢工作時,可擴大範圍,多與業內小商會溝通,小商會的會員多主攻本地市場,了解實際需要。他更建議,政府可提供更貼地的支援,如「百分百擔保特惠貸款」的還款期,可再延長3年,並按個別中小企需要,可選擇延遲還款和如期還款,有助中小企理順現金流。

商會期望 先處理港經濟內循環

香港各界商會聯席會議秘書長沈運龍稱,疫情下不少中小企需以按揭貸款做生意,強調「還息不還本」計劃確實為許多中小企帶來幫助,期望計劃屆滿後可延長至年尾旺季。他同時是珠寶品牌古珀行的董事,公司主要從事出口業務,面對奢侈品市場萎縮等挑戰。

然而,沈坦言在出口方面「只要銀行不收回貸款,出口業就仍可捱下去」,故沒有期望在出口方面的特別援助措施,反而更期望港府可先處理本港內部經濟循環。他希望當局增加本地旅遊支援外,亦建議派發消費券,支持設立失業保險制度,希望刺激本地消費。

餐飲業方面,位於何文田及荃灣的咖啡店Peko Peko創辦人之一梁小姐指出,仍未收到第四輪抗疫基金。她期望新一份預算案,可以着力在減免稅收、電費和租金等方面。她解釋,現時每天的營業額都用作交租。她認為,預算案可繼續為受影響處所,提供保就業計劃。

廠商會籲政府 支援深受打擊行業

財政司司長陳茂波發表新一份財政預算案,面對過去一年的疫情打擊、經濟不景,各界對預算案亦有不同期望。

香港中華廠商聯合會(廠商會)會長史立德昨出席活動時表示,希望政府可更精準地支援「處於水深火熱」的市民及企業,特別是深受疫情打擊的行業,包括零售、旅遊、製造業廠商等。他舉例,政府可如過往般,繼續推行優惠貸款計劃。

他認為,於防疫抗疫基金下推行的保就業計劃全面支援各個行業,但有欠精準。他坦言,有部分行業不太受疫情影響,例如保安、超市、家居用品等,冀政府可保留資源協助更有需要支援的行業。

隨着第一批疫苗抵港,史立德期望港府可盡快與廣東省協調重新通關的安排。他解釋,業界有部分廠商已一年未能到內地管理廠房,營業受影響。

資料來源:香港經濟日報 (2021年2月24日)

5、世貿應港要求設專家組 審理產地來源標記爭端

【本報訊】就早前美方對香港實施產地來源標記新規定一事,世界貿易組織爭端解決委員會同意香港的要求,將會成立「專家組」審理有關爭端。

商務及經濟發展局發言人表示,目前已有13個世貿成員有意以第三方身份參與專家組的會議,顯示他們對這個關乎多邊貿易制度,以及世貿成員平等權益問題的關注。

港強烈反對美實施新規

特區政府於1月25日舉行的爭端解決委員會會議上,首次要求根據爭端解決機制成立專家組審理有關爭端。按機制,投訴方提出申請成立專家組後,爭端解決委員會最遲應在該申請被列入議程後的第二次會議上設立。

香港特別行政區駐世貿常設代表羅志康於爭端解決委員會會議上發言,重申香港強烈反對美國單方面和不負責地對香港貨品實施產地來源標記新規定,指出有關做法不但毫無理據,更違反多項世貿規則,損害香港作為世貿一員的權益,有必要成立專家組予以跟進。

資料來源:香港經濟日報 (2021年2月24日)

6、利華1560萬購卓世助添客戶群

利華控股(01346)上周宣布,以200萬美元(約1560萬港元)收購本港從事訂製工藝服裝的卓世(Champion System),利華控股主席司徒志仁表示,由於工藝服產品要求特別技能組合,收購卓世有助公司擴大客戶群,並實現交叉銷售等協同效應。

卓世從事訂製工藝服裝,包括高性能單車、跑步及三項鐵人服裝,除了本港市場,銷售渠道亦遍布全球,主要客戶群是奧運代表隊、專業比賽運動員,亦有大型企業旗下單車團隊等。該公司於2006年起與香港單車隊合作,贊助香港單車隊工藝服裝出戰奧運,包括黃金寶及李慧詩等。司徒志仁說,公司有意拓展專業及小眾市場,工藝服裝是其中一種類,可以令利華旗下服裝類別多元化。

他指出,雖然新冠肺炎疫情影響去年生意,但無礙公司繼續收購小型項目,認為現時是收購的好時機,藉此加快拓展業務。自2019上市後,公司收購了高端毛衣製造商Vista Apparels、高端技術外套製造商瑞士利維高的若干應收賬款、存貨的預付款項及採購訂單,不排除繼續收購。他稱,收購項目後,公司本身的管理層仍會留任,他們具多年營運經驗,不擔心日後難以整合。

另外,他透露,公司已於五六年前剝離廠房業務,減少了廠房經營開支,並以輕資產模式營運,為客戶做好增值服務,現時與40至50間廠房為合作夥伴,主要在越南、印尼地區等。

疫情帶動家居服及運動裝銷量

司徒志仁舉例,最近緬甸政治動盪,影響當地廠房營運,公司可以把訂單轉到其他地區生產。利華客戶除了高檔品牌外,亦有電子商務客戶,其中包括Bonobos及Boden。他直言,網絡原生品牌與傳統品牌的落單形式有分別,網絡原生品牌要求數量小,但要款式多及出貨要快,他們亦願意給予較理想價錢。

新冠肺炎疫情影響全球,他稱,去年第二季整體歐美服裝品牌銷售下跌六至七成,直到現時為止,部分歐美國家因疫情仍實施封城措施,消費市場疲弱。雖然疫情打擊各行各業,但對電商的影響會較傳統實體門店小。服裝消費方面,因疫情下很多人在家工作,辦公服裝最受影響,反而家居服及運動服銷售向好,近期公司服裝訂單趨向已較去年穩定。

資料來源:信報財經 (2021年2月22日)

7、牛仔文化未來趨勢

有一百多年歷史的牛仔褲,可說是最歷久不衰和無國界的服飾,不論種族、性別、年齡的男男女女,老老嫩嫩,很少會沒穿過牛仔布做的服裝,對現代人來說,牛仔褲早成為衣櫃裏的must have item。以牛仔時裝及本地文化為題的「香港牛仔節」剛剛展開,除了可以了解到這種最受人類歡迎服裝的過去與現在,還有機會看到其未來。

由香港知專設計學院(HKDI)主辦、創意香港贊助的「香港牛仔節」,今年是第二屆舉行,以「明日牛仔」為題,首部分活動(2月19至25日舉行)已於中環元創方展開。

由於疫情關係,今屆牛仔節其中一些活動亦同步於線上進行,本地及海外的牛仔愛好者,可以一同探索牛仔服飾發展。例如是全天候網上360導覽,10多間公司和品牌展示最新的牛仔布料及發展技術,其他展品包括牛仔機器品牌Jeanologia展示的鐳射印刷技術及牛仔洗水技術、JACQUARD™ BY GOOGLE智能LEVI'S®牛仔褸等,極具前膽性。

交流平台

「香港牛仔節」的核心項目之一是牛仔市集,這個市集提供一個結合本地和國際牛仔設計專才的國際交流平台,讓「牛仔發燒友」可以隨時隨地欣賞及購買心頭好。

本屆市集有多位本地和海外設計師或藝術家參與,展示和銷售他們的牛仔布產品和藝術品,大家可以見到牛仔布在日常生活中的可塑性。當中多名本地及海外的年輕設計師或藝術初創公司被挑選為新進設計圈的一員,藉以支持年輕設計師發展初創事業。

市集設有五大區域,包括:1.「流行牛仔時裝Contemporary」展示不同牛仔作品,突顯其永續性及可穿性;2.「牛仔飾品Accessories」陳列牛仔布物料製作的時尚飾品;3.「牛仔手工藝品Art & Craft」結合牛仔布及藝術的手工藝品;4.「再造與古著Remake & Vintage」售賣及展出著名古著店的收藏,亦會售賣由一眾設計師運用解構及再造概念設計的產品;5.「海外設計與藝術Overseas Designers & Artists」展示海外知名的設計師及藝術家的作品。

大會又邀請本地和海外的牛仔布設計師和藝術家於活動期間舉辦20多個牛仔工作坊,將他們引以為傲的牛仔布工藝知識,與本地的設計學生和學童分享,藉以培育明日之星。部分設計師更開設線上工作坊,將材料包預先寄給參加者,即使留在家中亦能體驗到牛仔飾品製作的魅力。

線上研討

牛仔布業的技術日新月異,為推廣牛仔布業的技術發展,在牛仔節期間特舉行Online Denim Forum線上牛仔研討會,邀請9位知名牛仔品牌和製造商的代表,分享有關牛仔行業最新趨勢和創新技術。

大會亦會舉辦青年設計才俊座談會,鼓勵青年設計人才與設計學生以及公眾分享他們的設計理念和業務發展心得,期間更將展示「國際牛仔設計交流項目」的作品,各牛仔愛好者屆時可透過線上形式收看。

「香港牛仔節」第二部分活動將於3月2至28日舉行,有關詳情將於「香港牛仔節」大會網站http://www.hkdenimfestival.com公布。

資料來源:信報財經 (2021年2月20日)

8、Gap計畫7月退出英國和歐洲實體零售市場

核心提示:Gap計畫7月退出英國和歐洲實體零售市場,關閉英國和愛爾蘭門店。Gap已提出要在7月之前支付租金,但只能以較低的利率支付。

中服網消息,快時尚品牌Gap將於在7月關閉其在英國和愛爾蘭的所有門店,但目前在退出英國(和歐洲大陸)實體零售的計畫方面正面臨與房東的爭執。

據報導消息稱,Gap已提出要在七月之前支付租金,但只能以較低的利率支付。對於目前面臨歷史上租金緩慢的房東和許多租戶拒絕支付房租或希望轉為基於營業額的交易的房東來說,這將是一個主要問題。

去年秋天有消息傳出,Gap正在探索在歐洲成為僅線上業務的選擇,儘管也有人建議零售店可能會達成特許經營協定。

Gap目前在英國經營著95家商店,儘管由於目前的封鎖而關閉了。在截至2020年2月的一年中,Gap為表現不佳的商店記錄了超過300萬英鎊的減值費用,這清楚地表明,Gap的問題不僅與大流行有關。

在該財政年度,Gap英國零售額下降了近10%,至1.95億英鎊,營業虧損超過4000萬英鎊。

資料來源:贏商網 (2021年2月23日)

9、Gap Inc. Says Digital Boom Sped Up Automated Warehouse Plans

Like many apparel retailers, Gap Inc. has seen the digital writing on the wall, and now it’s investing to support its stated ambition of driving half of all sales through the web by 2023.

The San Francisco-based clothing chain expects to break ground on a new Texas distribution center in April. The 850,000-square-foot location, augmenting a warehouse network spanning Arizona, California, New York, Ohio, Tennessee, and Ontario, Canada, will leverage a new fleet of Kindred robots helping to process 1 million units daily at full capacity.

Gap Inc. said it reworked the timeline for this project in light of pandemic-influenced trends around online shopping.

The highly automated facility will feature a full array of systems maximizing efficiency and output. Each Kindred Sort Orb’s robotic “arm,” surrounded by cubbies, will rapidly and accurately sort batches of units assigned to myriad digital orders. An automated storage and retrieval system offers a storage capacity of approximately 450,000 cases, employing automated cranes that deftly navigate 24 aisles of storage space to return or collect thousands of cases.

Two stacked Bombay unit sorters comprise a conveyor belt of trays that split open in the middle and drop product into the appropriate chute. Though one can process 500,000 units daily, the second sorter will come in handy for demand spikes, enabling the facility to handle up to 1 million units during peak season, a spokesperson told Sourcing Journal.

The clothing firm also opted to include auto-baggers that quickly and efficiently wrap e-commerce orders. Automating this simple but repetitive task means the retailer can assign associates to high-value operational processes elsewhere in the facility, the spokesperson added.

The new facility will support Gap Inc.’s growing digital business, which surged 61 percent in the third quarter. It will initially serve the Old Navy brand, which saw a “meaningful” online acceleration in Q3, though the company pointed out that many of its other facilities simultaneously serve e-commerce and retail stores.

Gap Inc. chief operating officer Shawn Curran said the new facility supports the company’s three-year strategy and plan to double the online business, adding that it “needed to expand our fulfillment network to provide a great experience for our customers today and ensure we have the ability to grow in the future.”

When considering where to put down roots, Gap Inc. noted that the Longview location’s local jurisdiction dovetails with the “aggressive schedule” for construction, and cited the area’s labor force as “sufficient to support our operational requirements,” the spokesperson added. The retailer also took advantage of incentives that is described as beneficial for company and community alike.

Expected to be fully operational by August next year, the distribution center is slated to support 500 full-time jobs by the end of 2023, expanding to 1,000 over five years. By 2026, Gap Inc. aims to attract another 1,000 seasonal and part-time positions.

Source: www.sourcingjournal.com (24 Feb 2021)

10、Retailers and brands express concern at Myanmar coup

Retailers and brands accounting for around 40% of Myanmar's garment exports – including C&A, H&M Group and Inditex – say they are deeply concerned about the current developments in the country following the recent military coup.....

Read More: https://www.just-style.com/news/retailers-and-brands-express-concern-at-myanmar-coup_id140786.aspx

Source: www.just-style.com (19 Feb 2021)

11、Fashion Companies Straining to Pay ‘Unexpected’ Cargo-Related Charges: AAFA

Federal Maritime Commissioner Rebecca F. Dye said she will issue information demand orders to ocean carriers and marine terminal operators (MTOs) to determine if legal obligations related to detention and demurrage practices are being met.

The issue has been percolating for months and earlier this month Steve Lamar, president and CEO of the American Apparel & Footwear Association (AAFA), sent a letter to the Federal Maritime Commission (FMC) urging it to take immediate steps to stem the surge in contract violations and the spike in detention and demurrage charges.

“Because of the pandemic, our members are already facing enormous challenges, battling a huge slump in demand that has led to store closings, furloughs, layoffs and bankruptcies, while trying to respond to the crucial need for face masks and other personal protective equipment (PPE) and the swings in demand for different types of clothes, shoes, and accessories,” Lamar wrote.

“Meanwhile, a convergence of issues, exacerbated by the COVID-19 pandemic, has created unprecedented shipping problems and delays, for beneficial cargo owners (BCOs), for truckers, for ports, for terminals and for carriers,” Lamar continued. “However, BCOs have borne the brunt of this impact. Despite having contracts in place, our members have had to pay unexpected and unplanned surcharges, premiums, and/or spot rates to get their cargo on ships. Even then, their cargo has still been rolled, forcing them to miss key delivery dates, leading to further lost sales (particularly for seasonal product) or further charges from their customers.”

In addition, Lamar said AAFA members have faced a spike in detention and demurrage charges “for situations completely out of their control.”

The FMC orders are being issued under Dye’s authority as the Fact Finding Officer for “International Ocean Transportation Supply Chain Engagement.” Targets of the orders will be ocean carriers operating in an alliance and calling the Port of Los Angeles, the Port of Long Beach, or the Port of New York & New Jersey. Marine terminal operators at those ports will also be subject to information demands.

The demand orders will also require carriers and MTOs to provide information on their policies and practices related to container returns and container availability for exporters. Failure of carriers and MTOs to operate in a way consistent with the Interpretive Rule on Detention and Demurrage that became effective on May 18 might constitute a violation of a statute that prohibits unjust and unreasonable practices and regulations related to, or connected with, receiving, handling, storing or delivering property.

“We urge the Federal Maritime Commission to fulfill its oversight role to ensure that contracts are honored and that its new policy on detention and demurrage charges is followed,” Lamar addd.

The FMC said information received from parties receiving demands may be used as a basis for hearings, enforcement action or further rulemaking.

Source: www.sourcingjournal.com (22 Feb 2021)

12、Inside H&M’s Sustainable Cellulosic Fiber Investment

Swedish fiber innovation group TreetoTextile, which was founded by the some of the Nordic region’s leading companies, is investing big to bring its sustainable cellulosics to a wider audience.

Founded by fast-fashion firm H&M Group, global home goods giant Inter Ikea Group, paper producer Stora Enso, and LSCS Invest, TreetoTextile announced Tuesday that it will pump 35 million euros ($42.5 million) into building out a pilot plant in Sweden in an effort to commercialize its alternative cellulosic fiber for use across multiple industries.

The plant opening marks a “critical next step” in bringing the fiber to market with scalable technology and low manufacturing cost, TreetoTextile said. Made from a bio-based regenerated cellulose sourced from trees, the versatile fiber is developed using 33 percent less energy, 70 percent less chemicals and 80 percent less water than conventional fibers. What’s more, the process was engineered to suit large-scale production, and contains a recovery system so that processing chemicals can be reused.

Investors will foot more than 27 million euros-worth ($32.7 million) of the bill for the new plant, TreetoTextile said, supplemented by a 7.6 million-euro grant (more than $9 million) from the Swedish Energy Agency. The plant with be built at Stora Enso’s Nymölla mill in southern Sweden this spring, with the expectation that it will eventually produce 1,500 tons of fiber per year.

The demo plant will be strategic for optimizing the process for the use of different types of dissolving wood pulp, TreetoTextile CEO Sigrid Barnekow told Sourcing Journal. The first round of production will use pulp from Stora Enso’s Enocell mill in Finland, which pulls wood from sustainably managed forests through a Forest Stewardship Council-certified process.

While the plant will be housed at paper producer Stora Enso’s mill, Barnekow said that it will be run independently. “For us it is very convenient to connect directly to a mill and their existing production infrastructure, but our operations are separate from theirs as their operations will continue without any change,” she said, adding that the mill is “highly excited” to play host to a new technology that aims to support the global textile industry.

Barnekow said the demonstration plant will allow her team to “verify the technology in a full-scale similar setting, and further fine-tune the process,” with an eye toward increasing sustainability and testing out alternative cellulose sources. “The objective is to provide a new man-made cellulosic textile fiber with as strong sustainability performance as possible, at the same time to an attractive cost level,” she added.

TreetoTextile’s current process relies on the dissolution of pulp in a cold alkaline solution that “does not come with any air emissions, residue streams or involve carbon disulfide,” Barnekow said. Meanwhile, water and chemicals are recovered and reused to repeat the process.

When asked when the fiber is expected to hit the mainstream market, the CEO said that he hopes to see its introduction within the next few years. “First we need to ensure our process works in full scale conditions and successfully run our demo plant operations,” he added.

Source: www.sourcingjournal.com (23 Feb 2021)

13、Fung Business Intelligence : Asia Sourcing Update - South and West Asia

Asia Sourcing Update_South and West Asia (Bangladesh, India, Pakistan and Turkey)_February 2021

https://www.fbicgroup.com/sites/default/files/ASU_SW%20Asia_202102.pdf

Source: Fung Business Intelligence (25 Feb 2021)

14、Better Buying Deep Dive Report Vol.2

“Better” Design, Development, and Calendar Management

Latest report offers a deep dive into the critically important purchasing practices related to design, development, and calendar management – which captures the range of activities required to develop new products according to a buyer’s specifications and produce them within a buyer’s timelines. It’s clear brands, retailers, and suppliers can improve their financial, social, and environmental performance through better design, development, and calendar management practices. Read the full report to find out on how companies engaging with Better Buying over the last two consecutive ratings cycles, show improvements in design and development practices and calendar management.

Link to the full report: https://betterbuying.org/wp-content/uploads/2021/01/Deep-Dive-Report-21.pdf

Source: www.betterbuying.org (27 Jan 2021)