2021.08.06

INDUSTRY NEWS - 2021.08.06

1、即日暫停廣東省以外從其他內地地區通過“回港易”計劃返港獲豁免檢疫安排

因應內地最新疫情發展,今日(8 月 5 日)起,除廣東省外,從其他內地 地區返港的香港居民,將暫時不能通過“回港易”計劃返港而獲豁免檢疫。這是繼 8 月 4 日起把澳門納入“回港易”計劃暫不適用風險地區名單 後另一須採取的防疫措施。

根據有關安排,在抵港當天或之前 14 天曾逗留在廣東省以外其他內地地 區的人士,在抵港後將不會獲得豁免檢疫,而必須進行 14 天家居強制檢疫,另在檢疫期間須在抵港第 3 天、第 7 天和第 12 天,以及完成檢疫後 的抵港第 16 天和第 19 天接受強制檢測。因應已完成疫苗接種而調整強制 檢疫期至 7 天的安排並不適用。

香港特區政府發言人表示,上述安排於 8 月 5 日淩晨零時起生效,即使在 此前已通過”回港易”計劃登記返港的人士,亦不會獲豁免檢疫。政府會 向已在”回港易”計劃下登記返港而受影響的市民發出手機短訊,通知他 們有關的最新安排。

香港特區政府會繼續與內地及澳門當局就三地疫情防控措施保持緊密溝通和聯繫。 有關“回港易”計劃的詳情,可瀏覽“2019 冠狀病毒病專題網站”: return2hk.gov.hk 或回港易.政府.香港。

資料來源:香港特別行政區政府駐粵經濟貿易辦事處 (2021年8月5日)

2、緬軍事政變半年 三大困局未解 示威未平息 疫情未受控 國際社會未認可

【明報專訊】緬甸軍方今年2月1日發動政變至今足有6個月,然而軍政府對內未能穩定局勢,既未能平息示威,亦無力處理新冠疫情,對外則缺乏國際社會承認。東盟國家外長周一(2日)將開會決定負責緬甸問題的特使人選,路透社引述消息指東盟曾討論任命多於一人處理緬甸問題,但未達共識。緬甸軍政府領袖敏昂萊(小圖)周日(1日)發表電視講話,再承諾會舉行多黨派選舉,又表示軍政府準備好跟東盟任命的特使合作。

敏昂萊承諾辦多黨派選舉

緬軍政變後半年,示威並未完全結束,第二大城市曼德勒上周六(7月31日)有學生參與反對軍政府示威,他們騎着電單車在市面行駛並揮動旗幟,表示拒絕任何與軍方談判以恢復文人管治的可能性。除了示威未息,新冠疫情亦成緬甸社會當前挑戰。當地新冠病毒確診病例自6月底急升,而上周六單日新增4725宗新症。緬甸醫護設施本就落後,民主派醫護人員罷工抗議軍政府、民眾避免到軍方醫院求醫,令當地新冠病毒疫情雪上加霜難以受控。

前聯合國緬甸人權狀況特別報告員、人權關注組織「緬甸特別顧問委員會」(SAC-M)創始成員李亮喜更指出,軍政府利用疫情作為武器對付反對軍政府的平民及醫護。她稱軍政府拘捕支持公民抗命運動的醫生、拒絕懷疑支持民主運動的平民入院治療,又拒絕向未獲軍政府支持的人出售氧氣。

疫下料經濟收縮18% 貧窮人口倍增

新冠疫情威脅緬甸的民生經濟。世界銀行在上周一(7月26日)發表的報告中,警告緬甸今年的經濟因為疫情及政變而面臨收縮18%,貧窮人口比率到明年初或會較2019年的水平增加一倍以上。世銀警告有關危機將對人命、生計、貧窮和未來增長帶來破壞性影響。半島電視台引述一名在緬甸的外國投資者形容緬甸經濟正處於「自由落體」狀况:「軍政府在任何意義上都無法執政。除了政治動盪外,他們亦未能應對疫情導致封城而帶來的經濟影響。」

緬甸平行政府「全國團結政府」(NUG)發言人薩薩(Sa Sa)稱目前的軍政府是「失敗的政變及失敗的政權」,在各方面如醫療、教育和經濟都未能發揮政府功能。然而半島電視台指出,NUG亦未能扭轉疫情、打破政治困局——NUG未有闡述人道主義援助政策,或說明國際合作伙伴能夠如何在軍方控制的地區提供援助。

軍政府再提名駐聯國大使人選

負責向聯合國大會報告各國代表資格的「全權證書委員會」(Credentials Committee)下月召開,NUG和缺乏國際社會認同的軍政府都尋求取得國際認可其地位。軍政府未能成功將支持前國務資政昂山素姬政府的駐聯合國大使覺莫吞解職後,軍政府外長本月再提名已離開多緬軍26年的昂圖賴(Aung Thurein)接替覺莫吞。

東盟被視為處理緬甸局勢的最佳平台,但東盟自4月開始尋找緬甸問題特使人選,至今仍然未有定案。路透社引述消息指東盟屬意輪任主席國文萊的外交部第2部長艾瑞萬(Erywan Yusof)為特使,並有數名「顧問」從旁協助,但東盟高級官員上周四開會後未達成共識。艾瑞萬上周五晚稱希望周一會有決定。惟有關人選亦需要緬甸同意;敏昂萊周日表示緬甸已準備在東盟框架內跟東盟合作,包括與東盟的緬甸特使對話。

東盟緬甸問題特使人選未達共識

美國國務院官員上周六表示,國務卿布林肯本周將連續5天跟東南亞國家領袖舉行視像會議,包括東盟10國外長的年度會議,及與該區國家個別會面,作為顯示該區為是美國的優先事務,同時解決緬甸危機。

資料來源:明報 (2021年8月2日)

3、工人在廠吃住引爆越南疫情

(星島日報報道)越南要求企業讓工人「在廠吃住」,卻陸續引爆群聚感染。 越南新一波新冠本土疫情肆虐,短短三個多月確診人數突破十五萬。南部的疫情以重災區胡志明市為中心,並陸續向外擴散至鄰近的平陽省、隆安省等地。為兼顧防疫與經濟發展,南部部分省市自七月中陸續祭出新政策,企業要做到讓工人「在廠吃住」才可繼續營運,儘管必須定期對員工做快篩,但廠內交叉感染個案仍不斷攀升。工業重鎮平陽省已連續四天上千人染疫。《越南快訊》報道,民營的經濟發展研究委員會向越南總理范明正遞交文件,指出該政策只應在疫情控制較好的地方實施,衛生主管單位也須公布廠內感染的醫療計畫。

資料來源:星島日報 (2021年8月3日)

4、Nike’s supplier Esquel Group scores a rare win in removing its Xinjiang apparels unit from US forced-labour sanctions list

● US inter-agency body voted to remove Changji Esquel unit from the so-called entity list under certain conditions

● The shirtmaker and the US government are in discussions over the conditions

Esquel Group, one of the world’s biggest shirtmakers, won a rare victory in its effort to get one of its subsidiaries removed from a United States government blacklist over allegations of ties to forced labour in western China.

The End-User Review Committee, a US inter-agency body, voted to remove its Changji Esquel unit under certain conditions from the so-called entity list, which prohibits it from buying from American suppliers, according to a joint motion filed on Tuesday in US District Court for the District of Columbia.

The Hong Kong textile company, which counted Nike, Patagonia and Tommy Hilfiger as customers before the blacklisting, sued the US Commerce Department and other US government agencies and officials in federal court last month over Changji Esquel’s inclusion on the entity list.

“The parties are currently engaging in further discussions regarding those conditions,” the motion said.

In the motion, the parties asked the court to delay the next hearing scheduled in the case until September while the discussions continue. The litigation is ongoing.

The Changji Esquel unit, which is based in China’s Xinjiang Uygur autonomous region, was added to the entity list a year ago as the US sought to punish companies over alleged human rights abuses against Uygur Muslims in the region. Esquel has repeatedly denied the allegations and said its unit was improperly added to the entity list with “no notice or supporting evidence”.

An Esquel representative declined to comment on Wednesday on the nature of the conditions set by the committee. The Bureau of Industry and Security, which oversees the entity list, did not respond to a request for comment.

In its lawsuit, Esquel, which has had a presence in Xinjiang for a quarter of a century, said it has tried to engage with the US government to correct the record, but had received no meaningful response or evidence to support the inclusion of its Xinjiang unit.

The US Commerce Department has previously declined to comment on the lawsuit.

The Changji Esquel unit was one of 11 Chinese companies sanctioned by the Commerce Department last year for alleged ties to forced labour in Xinjiang. The US blacklisted another 14 Chinese companies over their role in suspected human rights abuses in Xinjiang on July 9.

The Xinjiang region produces about 85 per cent of China’s cotton and about a fifth of the global cotton supply.

The US government, as well as human rights groups and a United Nations committee, claim that as many as 1 million Uygur Muslims, Xinjiang’s largest ethnic group, have been detained in “re-education centres” and subjected to indoctrination, torture and forced labour.

Source: www.scmp.com (4 Aug 2021)

5、Bangladesh apparel factories reopen during strict lockdown

The Bangladesh Government has allowed apparel factories, including textile and readymade garment (RMG) and all export-oriented industries, to reopen despite Bangladesh experiencing high Covid-19 rates, according to The Financial Express in Bangladesh.

Over four fifths of apparel factories reopened in Bangladesh on Sunday (1 August) with at least 80% of garment workers returning to work as soon as it was allowed, according to a report in The Financial Express.

France24 also reported on the reopening of factories during the lockdown and claimed hundreds of thousands of Bangladeshi garment workers rushed back to major cities making train and bus stations busy.

The official Bangladesh figure for Covid-19 cases is 1.2 million and more than 20,000 deaths, however experts believe the real figures are at least four times higher.

Bangladesh is the third largest garment exporter after China and Vietnam. The industry has become the foundation of the economy so despite increasing Covid-19 rates, the Bangladesh Government made the decision to reopen the 4,500 apparel factories during lockdown.

In fact, France24 reported that Mohammad Hatem, vice president of the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), said up to US$3bn worth of export orders were at risk if factories had stayed closed. He added: “The brands would have diverted their orders to other countries.”

As many as 2,312 of the 2,725 BGMEA, BKMEA and BTMA-registered apparel factories, based in Dhaka, Gazipur, Narayanganj, Chattogram, Mymensingh and Khulna, reopened on Sunday with a total of 463 remaining closed, according to the Financial Express.

The Financial Express pointed out, labour leaders are not convinced a Covid-19-secure protocol is being followed in apparel factories apart from the wearing of face masks. It also claimed the labour leaders have said no wages should be cut due to the factories being closed during the lockdown and workers should not lose their jobs if they cannot go back to work until lockdown is completely lifted on 5 August.

Fazlee Shamim Ehsan, a leader of Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), claimed the factories recorded 87% to 90% presence of workers on the first day of operation on 1 August.

Just Style had not received an official comment from the BKMEA or BGMEA at the time of publishing this article.

Source: www.just-style.com (3 Aug 2021)

6、90% of Vietnam’s Garment Supply Chains ‘Broken’

As Vietnam battles its worst coronavirus outbreak to date, more than one-third of its textile and garment sector is in limbo, the Southeast Asian nation’s leading industry group said this week.

Surging Covid-19 rates have forced 30 percent to 35 percent of the country’s apparel and footwear factories to suspend operations, Vu Duc Giang, chairman of the Vietnam Textile and Apparel Association (VITAS), said at an online meeting on Monday. Up to 90 percent of the country’s supply chains, he added, are “broken,” intensifying sourcing headwinds that have led to shipment delays, bare shelves and higher prices. Companies from spider-silk producer Kraig Biocraft to shoemakers Puma and Wolverine have all lamented their challenges in Vietnam in recent weeks.

“I think that a number of these factories will even have to close for a long time, especially small and medium enterprises,” Vu said.

Most of these businesses, he noted, are unable to afford the live-work accommodations that support the health ministry’s “3 in one spot” guidelines, which require employees to work, eat and sleep in one location to curb the spread of infection.

Vaccination rates in Vietnam are also abysmally low, particularly in key production areas in the southwestern and southeastern provinces. According to data from the health ministry, Vietnam has fully vaccinated only 700,000 people—or less than 1 percent of the country’s 98 million-strong population—since it rolled out its program in early March. The country has logged 174,000 cases and more than 2,070 deaths, most of them within the past month.

VITAS has repeatedly lobbied the Vietnamese government to get more shots in arms—and it’s not the only one, either.

In a recent letter to Prime Minister Phạm Minh Chính, the American Apparel and Footwear Association, an industry group whose members include Adidas, Gap and Under Armour, urged authorities to “prioritize the distribution of vaccines to Vietnam’s apparel, footwear and travel goods industries” and keep a “vital part of the Vietnam economy intact.”

In the balance hangs the future of the country’s garment industry, which just last year unseated Bangladesh as the world’s second-largest exporter of clothing after China. Though both countries saw profits tumble after spooked brands canceled or hit pause on orders, Vietnam benefited from sourcing shifting from China at the start of the outbreak, dispatching $29 billion worth of apparel, or 6.4 percent of the global market, in 2020.

The current outlook appears less rosy for Vietnam’s 2.5 million garment workers, 80 percent of whom are women, according to the Better Work initiative. On Monday, China’s Pou Chen Corporation announced that its Ho Chi Minh-based Pouyuen Vietnam factory, which supplies footwear to brands such as Adidas and Nike, would be prolonging its already extended lockdown from Aug. 1 to Aug. 9. The facility had originally been scheduled to close from July 14-23.

Pouyuen Vietnam is merely a microcosm of a wider industry. Without serious intervention, the losses from stilled production lines will only add up.

“In the last five months of the year, businesses could only start exporting again if the pandemic situation is completely under control,” Vu said. “In the most optimistic scenario, we can only achieve about $32-33 billion.”

In light of Vietnam’s “consistent approach” to managing the pandemic, it’s unlikely that garment factories will be permitted to operate even with stricter health and safety guidelines in place, as seen in Bangladesh, said Sofia Nazalya, Asia analyst at risk analysis firm Verisk Maplecroft.

But while ongoing lockdowns will have “clear operational impact for apparel companies,” the situation is unlikely to be better in neighboring garment hubs such as Cambodia and Indonesia, “which are also experiencing similar spikes in cases, and equally slow, if not worse, vaccination rates,” she told Sourcing Journal.

Source: sourcingjournal.com (4 Aug 2021)

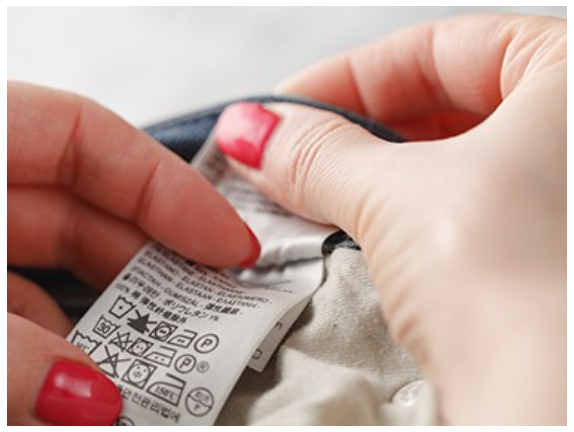

7、US care labelling is here to stay, rules Trade Commission

Care labelling will remain mandatory for apparel and certain textile goods sold in the US.

The Federal Trade Commission (FTC) voted in an open Commission meeting to retain the mandatory care labelling requirements for apparel and certain textile goods after a proposal in June 2020 to repeal the requirements.

The FTC said the Care Labeling Rule ensures American consumers continue to get accurate information on how to take care of their fabrics and extend the life of their clothes.

It added it would continue to consider ways to improve the Rule to the benefit of families and businesses.

The Care Labeling Rule has been in effect since 1971 and requires manufacturers and importers to attach labels with care instructions for garments and certain piece goods, providing instructions for dry cleaning or washing, bleaching, drying and ironing clothing. Public comments solicited by the FTC over the past decade show the Care Labeling Rule continues to provide valuable guidance and serve as an important tool for consumers, manufacturers, retailers, designers and dry cleaners alike.

In July 2020, in the middle of the pandemic, the Commission voted 3-2 to propose repealing this consumer protection altogether, the FTC said. Following that action, the FTC received more than 200 comments, with an overwhelming majority opposed to the repeal of the rule.

“The Federal Trade Commission first promulgated the Care Labeling Rule in 1971, with the goal of ensuring buyers were provided clear and accurate information on how to take care of their fabrics. Since then, the agency periodically has reviewed the rule, seeking public comments to ensure the rule is keeping pace with new developments and still providing buyers with relevant information,” said FTC chair Lina Khan in the open Commission meeting. “After careful consideration, I believe the record supports retaining the Care Labeling Rule and that it should not be rescinded.”

Submissions to the most recent public comment period led the Commission to conclude that repealing the rule would not be in the public interest. Many individuals and small businesses opposed the repeal, emphasising that buyers rely on labels to help extend the life of their clothes, it noted.

Other comments the FTC received from the apparel manufacturing and cleaning industries indicated that removing the labels would increase the likelihood that their customers’ items might be damaged in the wash and, as a result, expose their businesses to unnecessary liability.

The Commission voted 5-0 to issue a statement to notify the public that it will not repeal the Care Labeling Rule, as previously proposed.

Source: www.just-style.com (2 Aug 2021)

8、Asia Sourcing Update - South and West Asia (July 2021)

Bangladesh – Neutral

The new wave of COVID-19 outbreak in Bangladesh may prolong the country’s recovery; however, the reopening of retail stores in Western countries is raising hopes as exports are expected to return to pre-pandemic levels within months. According to the Export Promotion Bureau (EPB), export earnings from the apparel sector jumped by 10% year-on-year (yoy) to US$30.9 billion in 2020-21 fiscal year, following a rebound of apparel shipments. Though the sector is facing a price hike in raw materials, local manufacturers are optimistic about a full recovery in apparel exports by October 2021.

India – Neutral

The second COVID-19 wave in India peaked at the beginning of May. Since then, stringent lockdown measures were reimposed. The country’s manufacturing activities contracted for the first time in 11 months in June. The IHS Markit India Manufacturing Purchasing Managers’ Index (PMI) dropped to 48.1 in June from 50.8 in May. The index fell below 50 for the first time since July 2020.

Since mid-May, new cases and daily deaths have continued to fall. It is expected that mobility and economic activities will accelerate in the second half of the year if the pace of vaccinations picks up.

Pakistan – Positive

Pakistan’s economy showed encouraging recovery in fiscal year 2020-2021 (July 2020 – June 2021, henceforth FY2021) with a preliminary GDP growth rate estimation of 3.9% yoy by the National Accounts Committee; this is compared with a 0.4% contraction in the last fiscal year. The positive momentum is expected to continue in the coming months given several indicators: the strong output improvements in the large-scale manufacturing industries (a 14.6% yoy increase during July 2020 to May 2021), an excellent export performance, the reopening of economic activities, and the acceleration of vaccination.

The Pakistani government has set its growth target for the fiscal year 2021-2022 (FY2022) at 4.8% and promised to continue with its stimulus packages, solve the electricity shortage problem, optimize the tax structure, and improve the business environment.

Turkey – Positive

Morale in Turkey has strengthened as “normalization” ramps up. Most COVID-19 restrictions have been lifted as the country gets closer to the possibility of mass immunity with over 50 million vaccine doses already administered in a country of 82 million. In terms of vaccine supply, the first domestically created jab, Turkovac, is now under trial and aimed to be made ready by the end of summer.

With the sharp drop in daily COVID-19 cases below 5000 and relaxation on restrictions, economic activity has increased with the headline Purchasing Manager’s Index (PMI) elevating to 51.3 in June, compared with May’s 49.3; both manufacturing output and new orders rose. In terms of consumption, tourism will also get a boost as flights resume from Russia, Turkey’s number one visitor source.

There is confidence in the country’s second half 2021 economic performance, with JP Morgan revising the full year GDP growth forecast to 6.8%, up from 6.1%, despite a slowdown in loans and higher interest rates. Economic growth in the second quarter of 2021 specifically is expected to be 20% yoy, compared with a near 10% yoy contraction during the second quarter of 2020. Nonetheless, currency volatility and rising inflation are two key elements to follow in determining overall risks for businesses.

Click here to download the full report.

Source: Fung Business Intelligence (2 Aug 2021)